The staircase is an architectural construction structure to which special requirements for strength, operational reliability and safety are presented. In addition, the appearance of this constructive is of particular importance. After all, in addition to operational fitness, the staircase must logically fit into the exterior or interior, laconically decorating it. Materials and finishing materials play an important role, and rather their quality. When choosing materials, it is better to give preference only to high-quality samples, because the staircase is not up to one dozen years. Then what material is best to make a staircase on your own? Experience shows that ladders from concrete are the most durable. And today we will talk about how to make a concrete staircase yourself.

Why is this material that is the leader in the construction of stair structures? You can bring some major arguments. First, concrete has high strength characteristics, it can be given any form to achieve the necessary architectural expressiveness. And secondly, the staircase from concrete with his own hands is performed in two bills, which we will try to teach you in this article.

So, we have already time to note a couple of advantages of the use of concrete as the material of the manufacture of stairs. We think everyone knows that concrete is an artificial stone material, which is obtained by hydrating the cement-sand mixture and add large aggregate of the required fraction. Depending on the water-cement ratio and the brand of the applied cement, you can get the class of concrete class you need. Thus, each person is able to independently lay the necessary quality and durability of the future staircase. Of course, it all depends on the finances that you have: you can buy more expensive or cheap cement, add or add a large aggregate.

The construction of stairs from concrete is equally permissible both inside and outside the building. In addition, it should be noted as follows:

- Monolithic concrete structures are not afraid of dynamic loads, as they do not have elements that may be loosened;

- These designs are completely fireproof;

- Allow you to realize the most difficult design ideas;

- The manufacture of ladder from concrete provides complete freedom to choose finishing materials.

If we convinced you in the indisputable advantages of applying concrete, then we turn to the next stage.

Before starting work

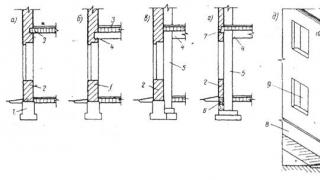

The concrete staircase can be made in several options. Before embarking, you need to choose a design. The monolithic one can make the entire staircase or exclusively cosos, which will subsequently installed precast concrete or wooden steps without risers. Of course, the second of the above constructs is much simpler in performance and is characterized by a smaller mass. However, it should be taken into account that in the recreation area, such stairs are inappropriate because of the lumen in the design, through which sand and dust with shoes passing through it can be poured through your heads.

Most often in private homes it is the monolithic design of concrete.

It should also be noted such a feature: the construction of stairs to the basement, on the veranda or attic, as well as the second floor of the building is made directly during the construction of the entire object. After the completion of construction and finishing works, it is not possible to construct a separate monolithic design. If you did not have time to think about the concrete staircase before the end of construction, then only a wooden or metal design will be able to help you out from the current situation.

After you have decided on a constructive solution, it is necessary to initially calculate the geometric parameters that carry the ability and, of course, the weight of the structure. Geometry, the mass and strength of the stairs are the main criteria for its safe operation.

Especially important is the accurate calculation for similar non-standard structures.

Stages of construction construction

The manufacture of concrete ladder includes three main stages, which, in principle, are typical for any designs of monolithic reinforced concrete:

Sometimes special composite rods are used to create a reinforced frame.

- Concreting. After the formwork and fittings were installed, go to the pouring of the concrete mix. An important process at this stage is to vibrate concrete for its seal and eliminate excess air.

The fill process of formwork concrete

Builders know that the installation of formwork is perhaps the most time-consuming process, in particular, if you are going to make a staircase with a complex geometry.

Tip!

If you decide to do not a simple marching staircase, but a complicated suitful spiral design, immediately contact your experienced specialists.

To create a similar design on your own forces, you can hardly succeed.

Start of work on the construction of concrete construction

So, as we have already spoken, the first step of the structure of the stairs is its preliminary calculation. Before the start of construction work you need at least to estimate the staircase sketch with the definition of all the dimensions. Here you should be guided by domestic design standards that say the following:

Standards of the size of reinforced concrete stairs.

The next important point is the choice of the base for the stairs. If the construction of the ladder is running outside the building, it can be equipped on a natural base. However, in this case, the soil must be pre-sealed and the underlying layer is arranged for a lot of reliability, for example, from rubble. Remember that the load on the ground should not exceed 1kg / cm2. Consider this when calculating the total weight of the structure and the choice of finishing materials for the stairs. In addition to natural, the stairs are also constructed on a concrete base that beams and foundations can serve.

Concrete staircase installed on the ground coating.

Making a concrete structure

After the fulfillment of all necessary calculations, the choice of base and preparation of building materials is embarked. The formwork is most convenient to do from waterproof plywood with a thickness of 18-20 mm. For the device, the racks and backups it is better to choose a bar, a cross section of which is 10x10 cm, and to perform the surfaces of the curvilinear form - a narrow board or a poler with a thickness of 9mm. When assembling the formwork, do not allow the appearance of slots and gaps, make sure that all surfaces are strictly vertical and horizontal. Connecting formwork elements Perform on self-stairs.

The working fittings of the staircase march is installed along the formwork. In the transverse direction, structural reinforcement is placed, which forms a flat grid with working rods. Currently, it is recommended to knit manually fittings without welding. Do not forget to also provide metal mortgage parts that will be needed for the device fencing staircase.

Collection of formwork for external staircase

When the armature is laid in the project position, proceed to concrete.

Important!

Concrete Pouring starts from the bottom stage and gradually climb up march.

The minimum class of concrete is B15. After set by concrete design strength, eliminate the formwork shields.

| Concrete class by compressive strength | Concrete strength for compression, kg / cm² | The nearest brand of concrete for strength |

|---|---|---|

| AT 5 | 65.5 | M 75. |

| At 7.5. | 98.2 | M 100. |

| AT 10 O'CLOCK | 131.0 | M 150. |

| At 12.5 | 163.7 | M 150. |

| At 15. | 196.5 | M 200. |

| IN 20 | 261.9 | M 250. |

| At 22.5. | 294.4 | M 300. |

| In 25. | 327.4 | M 350. |

| In 30. | 392.9 | M 400. |

| In 35 | 458.4 | M 450. |

| In 40. | 523.5 | M 500. |

Final steps

Here, in fact, all the main points on the construction of concrete stairs do it yourself. After the concrete fully gains strength, you can proceed to the march finish and the installation of the fence. In order not to create an excess load, it is recommended to use wood for finishing. From wood can be made both steps and handrails with balasines. Steps can also be separated by ceramic tiles. In principle, concrete is a material that is harmoniously combined with any other material, so you are not limited to the selection of finishes. In modern interiors, clean concrete surfaces are very often used, therefore, it is possible for your home the best option will be the minimum finish of the staircase protective compositions and grinding of surfaces. As you can see, the manufacture of the staircase is a time-consuming, but quite a row process even for a beginner in the construction sector.

Do not limit the standard structures, because concrete allows you to create the most incredible stairs.