Even if you do not build a country residence in 2-3 floors, without a staircase in the house, it is unlikely to be able to do. It can be concrete steps for a porch or a descent to a basement, in any case work with a solution will have to. The most difficult will be correctly assembled by formwork. Although the technology differs little from the usual mounting of the form under the foundation, the creation of a staircase of the volume projection of the staircase requires knowledge and patience. How to do everything right - read in our manual.

The formwork for the concrete staircase is usually made independently, as it is too expensive to order it at the factory for one time, and standard dimensions may not come in size. Traditionally, a tree is purchased for a frame - it is sufficiently light and durable. Boards take a thickness of 3-4 cm, and bars - a cross section of 10x10 mm (more powerful than for the foundation).

1. The decks of a complex form is better cut out of durable sheets of plywood 21 mm. Radius walls can be made of 9 mm panels, but that the solution does not squeeze them, it will be necessary to build a stiffness edge scheme.

2. It is better to use selflessness as a fastening, and not nails to make it easier for dismantling work and not to spill the whole design with a hammer. The length of the screws should be 40 mm more than the thickness of the sheet, the diameter is enough and 3.5-4 mm.

3. Separate deck elements are enhanced by wooden bars or metal corner. Special attention should be paid to the strengthening scheme of the bottom part of the form, if it is a formwork for a marching type staircase. Without the transverse ribs of the stiffness of the plywood under the weight of concrete, it will simply be joined.

4. The main difference between the staircase is steel reinforcement for concrete, which is mounted simultaneously with the form, and does not fit immediately before the fill.

Stages assembly

The formwork for the construction of the porch due to the relative simplicity of the design and the small size is easily manufactured on its own. It is impossible to call a full-fledged staircase, but it is better not to find the object technology. To begin with, you will need to make a project or sketch with all prone sizes. According to the requirements of the construction norms, the minimum width of the stationary staircase of any destination is 80 cm, the height of the steps 17, and their comfort depth - 29-30. Based on these parameters and you need to design a concrete porch. Deviations from the instructions are allowed only when the width is selected - it is better to correlate it with an external appearance of the house.

The steps in the diagram are located so that the imaginary line between the upper and lower platforms is at an angle of 25-30 ° to the horizon. If the basis for some reasons need to be reduced, you can make a sharper staircase with a slope to 45 °. But for the porch, such a solution is extremely undesirable, as wet or iced steps will become dangerous.

The plan is ready, the materials are chosen, the next stage is the installation of formwork and fill with concrete. We give the instructions for steps:

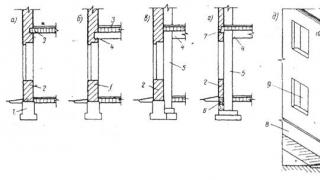

1. On a sheet of plywood, spread the side walls of the porch and cut both parts onto the electrol holder.

2. In accordance with the selected step, connect the walls with transverse bars - they will serve as a support for vertical panels. If the design is not too massive, wooden risers can be done without them.

3. Under the porch, dug a small hole, fall asleep with gravel and / or sand, and then ravibly. The adjoining wall of the base and the prepared soil to be fastened to the rubberoid.

4. Install the formwork box and consolidate it on vertical supports, burst into the ground so that the concrete does not squeeze the walls.

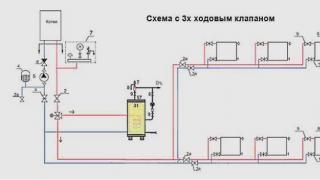

5. Inside to lay the reinforcement grid: the bottom belt in several centimeters from the soil, the top is separate under each step and the staircase site. You can simply collect the cell of the desired configuration using vertical jumpers, and then paste into the formwork box, laying flat stones with a thickness of 2.5-3 cm.

6. Aropoyasas rigidly tie with the releases from the base of the house.

7. A very wide span will have to additionally strengthen the nailed diagonal bars. They will compensate for the tensile loads, extrifying the boards of risers.

8. If the porch is planned to be equipped with railings, before filling to the reinforcement, you need to weld or tie the mortgage parts (cuts of rods or steel plates). According to the technology, they must perform several millimeters from concrete.

When the formwork for the porch is ready and reliably strengthened, you can move to concrete work. Almost immediately after the fill, finishing the staircase with tiled or decorative rubble, which are slightly intermitted in a liquid solution.

Design options

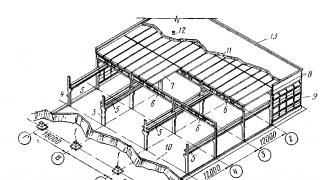

The monolithic staircase is characterized by high strength and reliability. It has no weaknesses, as there are no joints or seams. And the pouring of concrete into the formwork made with its own hands allows you to give march any shape. Concrete stairs can be both solid screw and marching. The last "collected" from one or 2-3 spans with transition sites between them. Spectacular option - steps on monolithic cosos. Powerful support beams carry the weight of the entire design, which you can give any direction or form.

For the entrance group, it is often made a porch of concrete in the form of a volume monolith with steps - we have already considered it in the formwork assembly manual. This is the easiest option from the point of view of installation, the most reliable in terms of strength, but very massive. The house uses only traditional staircases of the same thickness.

The selected design will determine the type of formwork:

- Print.

In such stairs, the steps on the one hand strive to the central axial line, and even agree on her at all. At the same time, their geometry is not always the same. The desired formwork elements will have to be cut separately for each step, which without serious experience is almost unrealistic. The manufacture of the bottom part of the form will complicate the whole process. The side walls are performed from the curved plywood, but the set of wooden planks will be stronger. For the screw marches of the staircase from concrete to build a formwork with their own hands is very difficult if you are not a professional. Therefore, it is better to overpay here, but order a metal frame at the factory.

- Movie stairs.

In the framework of the framework of the frame, this design is noticeably easier, since its main elements have the same shape and size. The deck is an inclined box with vertical walls for risers. When a multi-party ladder device needs a formwork with intermediate boxes for casting turntables. Spans can be attached to one side to the wall or arrange between two internal partitions. Occasionally there are marches, simply connected by the ends with plates of floors, but they take a lot of free space.

The formwork for one-time staircase is assembled with a whole span or separate cells under each step. But the fill of concrete should be done when the form is completely mounted. The solution is supplied to portions from the bottom up with breaks of about 15 minutes so that at the base he managed to grab a little and ensure an additional support when laying up the upper layers.

The formwork for the stairs in no way should hang on the top platform - it is necessary to provide reliable emphasis on the floor every half of the length. Vertical racks are fixed with thick wooden wedges.

The future surfaces of the steps and the ends of the staircase marches are cut down according to a predetermined pattern to prevent the dimensions. Each item before cutting is repeated, as the entire design should be collected tightly, without gaps and distortions.