Apartments with two levels, cottage or private house are now very popular. They help to establish life and comfortably accommodate on several floors to all family members. On the shoulders of contractors lies the manufacture of basic structures, and the manufacture of concrete stairs often has to take on the owners of the house.

High-quality concrete staircase with your own hands

The staircase from concrete is durable and reliable. This design has a large number of advantages. Its manufacture is similar to the construction of a concrete porch. Construction work begins with the fact that you need to calculate the number of steps. In height, they should be about 150-170 mm.

Then:

- Installing formwork. The first thing is set to the frame for the staircase. Its boards must be thick and durable to keep the entire staircase after concrete pouring occurs. After the installation of the overlap from the formwork is occurring into the gap between the steps. Formwork steps should also be strengthened and strengthened. Formwork is fixed with metal corners.

- Metal frame is stacked. The reinforced frame of the existing frame is placed on the bottom of the existing frame, he will be able to give more strength to the stairs. For a frame, a rod from a metal of 15 mm in diameter is used.

- There is a fill of the stairs. To pour the stairs, you need to start with the first step. Before the fill, you need to shake the mixture from the concrete with a regular trowel, thanks to this there will be air, which could continue to spoil the monolith of the finished design.

- Remaining formwork and reference pillars. 10 days after the fill occurred, the formwork is removed, the posts must be removed after 2 weeks. Then the concrete is grinding the grinding machine.

For easy removal of formwork from concrete After it froze, it is from the inside you need to be covered with waterproofing in one layer. It can be rubberoid or polyethylene film.

If the funds are not enough, you can not deal with the finishing of the finished stairs, or you can simply paint them.

In order to properly make a ladder from concrete, without resorting to the help of specialists, we need a competent calculation, then it is necessary to consider further construction and take into account all the details. Only then will the result be high-quality and beautiful.

How to make a concrete ladder for basement

In the basement, it is necessary to make a simple and convenient staircase, having a reliable fastening. The staircase made of concrete with one march will be the perfect option.

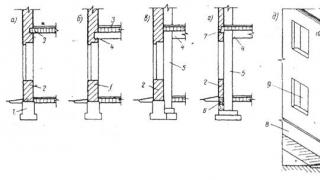

Concrete staircase can be erected in two ways:

- After performing a monolithic reinforced construction, while its base should be completely relying on the floor.

- Having installed the bottom formwork. It will help to provide free space under the design of the stairs.

Both methods can be performed by leaving the staircase to the wall, placing it between the walls or in the center of the room.

The design having a lower formwork requires an additional pair of metal channels No. 8, or iron pipes to strengthen the base.

Concrete, poured on the steps, must be dissolved by Celma.

Concrete staircase filling

Monolithic ladders from concrete are distinguished by durability and long service life. If you repair a similar design in time, it will be almost eternal.

Pouring is carried out in the following way:

- The process begins with the lower steps, first pour the first 2-3 below.

- Concrete is taught. It helps to increase the density and strength of the mass, at the same time removing air from it. When the fill is already produced, the concrete must be pushed using the reinforcement several times. However, builders with experience advise this with the help of a special mechanism of the building vibrator. It will be more reliable.

- The steps are leveled by a trowel, thanks to which they begin to acquire a finished look.

- Next, they pour in the same way all the upper steps.

- The finished flooding design from above is covered with a film, otherwise the concrete can be prematurely frozen, and cracks will appear.

Concrete for such a design should have crushed stone (10-20 mm). If it is large, he will be able to resist in steps, small can find out from formwork.

For such work, you need to take concrete with a minimum M200 brand and the minimum class B15. You can knew it or with your own hands, or order on RBU.

Installation of stairs: concrete steps in wooden trim

For the construction of stages from concrete, not only the desire, but also the necessary knowledge of the rules for which the design of stairs occurs. First you need to prepare a mixture of concrete for the staircase, then prepare the surface. Dimensions, number of steps, the design is poured concrete.

Prefabricated concrete structures on metal cosometers, the installation is carried out independently. The boosters are connected by bolts or weld to the beams of sites.

For concrete structures, finishing steps with a thickness of 22 mm are used, before this should additionally prepare a concrete base.

Mounting wooden steps on concrete, you need:

- Align the base from concrete.

- Provide good adhesion glue. To do this, the level is applied to the concrete.

- Dust the basis.

By installing wooden steps, do not use water-containing adhesives.

If there is no desire to engage in such a process yourself, a professional can always come to the rescue. After a contract and estimate are drawn up and construction work begins.

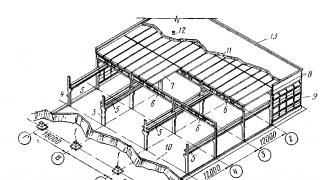

Concrete ladder device

The staircase is an architectural structure that serves to transition from one floor to another. It can be inner and outdoor, with a rotation of 180 degrees or a mirror (with a double frame).

When a concrete design device follows:

- Place the staircase, draw the steps;

- Collect formwork, install;

- Reinforcing marches stairs;

- Reinforce the staircase;

- Install the formworks of steps;

- Conduct the necessary work with concrete;

- Remove formwork, finish design.

Before reinforcement, the diagram in which the distance between each rod must be taken into account. They must be laid so that the grid turned out.

The outer attractiveness of the reinforced concrete staircase acquires due to high-quality finishes and the appearance of the handrails.

Finishing with natural stone and porcelain stoneware looks spectacular, but can only be applied for those designs that do not have curvilinear sites. The arrangement of ready-made staircases tree is the most expensive way to finish.

Concrete staircase with your own hands (video)

A house with more than 2 floors is simply obliged to be equipped with a reliable and strong staircase. In monolithic concrete structures, mass of advantages, besides, after decoration, they look like the customer wishes. They do not creak, do not voland and can be any form. From which we conclude that it is not for nothing that such structures are increasingly popular and conquer the hearts of people.