At the end of the construction work associated with the construction of the house, you need to take care of an equally important step - pouring the floor. To ensure reliability, durability and warmth, finishing materials are used: concrete and wood. Each has a number of disadvantages and advantages that must be taken into account when laying the floor in a private house with your own hands, since pouring the floor is a crucial part of home improvement.

The laying of the floor is carried out using the necessary materials and tools, a set of which must be prepared in advance. You will need the following building supplies:

- expanded clay;

- roofing material used for floor waterproofing;

- restrictive corners;

- trowels;

- shovels;

- polyethylene film, also used for waterproofing.

To facilitate work with concrete, a vibrotamper is used, which tightly compresses the solution and gives it porosity.

Starting any construction work, even before they begin, you need to think over an action plan, calculate the shortcomings of the materials used, and only then proceed with installation. They begin work with the floors, determining their level, which will ensure further evenness.

Starting any construction work, even before they begin, you need to think over an action plan, calculate the shortcomings of the materials used, and only then proceed with installation. They begin work with the floors, determining their level, which will ensure further evenness.

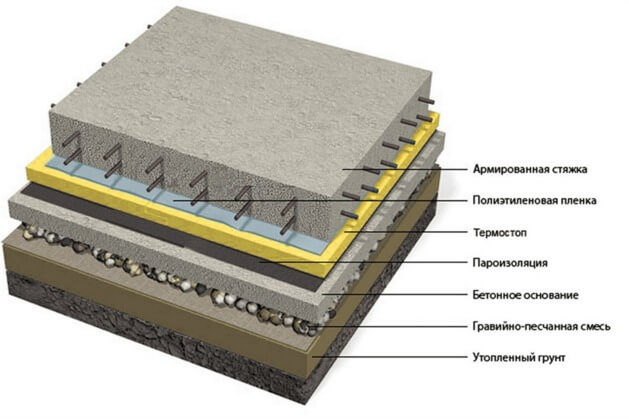

After the calculations are carried out, proceed to backfill the floor. Spread a layer of bulk materials, which will save concrete and make the floor even stronger. Initially, gravel is laid out with a thickness of approximately ten centimeters, after which it is rammed and filled with water. Top covered with sand of the same thickness as a row of gravel. The final layer will be crushed stone, but it also needs to be sprinkled with sand and then compacted well. The surface of bulk materials must be even and free from gaps.

The next step when working with the floor is insulation, which is necessary to prevent various influences. Further, the bearing capacity of the structure is increased with a material with more durable properties and formwork is used. When the preparatory work is completed, you can proceed to the screed.

We prepare the base

To ensure the reliability of the floor base, it is necessary to take into account the unevenness of the soil under the house, for this it is leveled and tamped to the required level in the floors. To provide waterproofing, the surface is smeared with clay and sprinkled with gravel and sand on top. After that, sheets of roofing material or plastic film are already laid out with a thickness of approximately a couple of centimeters. Docking places are glued with a tape specially designed for this.

Marking the level on the walls

Floors, or rather, their level, with the correct laying process, must correspond to the door thresholds. Therefore, when marking the level, you need to focus on them. Along the entire perimeter of the room, marks are made on the walls with the help of a building level. For convenience, stretch the fishing line or mark the lines with a pencil. Next, mark the zero mark and proceed to work, based on this point. To determine the center, a building or laser level is suitable.

Preparation of concrete mix

To fill the floor, a concrete solution is prepared, which must be done immediately before the start of construction work, since it tends to harden, and in this form it already becomes unusable. For the preparation of concrete you need: cement, crushed stone and. In order for the concrete mixture to be of good quality, sand with large particles is used, which does not contain clay additives and other organic substances. You should also pay attention to the consistency of crushed stone, which should consist of crushed gravel and have small particles.

To fill the floor, a concrete solution is prepared, which must be done immediately before the start of construction work, since it tends to harden, and in this form it already becomes unusable. For the preparation of concrete you need: cement, crushed stone and. In order for the concrete mixture to be of good quality, sand with large particles is used, which does not contain clay additives and other organic substances. You should also pay attention to the consistency of crushed stone, which should consist of crushed gravel and have small particles.

To prepare 50 liters of concrete, take 15 kg of cement, 50 kg of crushed stone and 35 kg of sand. Add water, depending on the percentage of moisture in bulk materials. To obtain a solution of the desired consistency, dry substances should be diluted with clean water gradually and evenly, then it will be possible to avoid the appearance of lumps.

Ground compaction and leveling

After construction work, a lot of debris remains, which must be removed before starting work with the soil. Before screeding the floor, get rid of cracks and uneven coatings.

They begin working with the soil by removing the top layer and only after that they begin to compact the soil. The process continues until the surface is smooth and firm. If it was not possible to level and compact it the first time, the upper layer of the soil is removed and covered with a dense material - sand.

Backfilling of the supporting base is started with gravel of the required thickness, while the material is distributed evenly over the area. The next step is backfilling with sand about ten centimeters thick. Each layer is poured with water and carefully rammed. Finally, crushed stone is used and treated in the same way as with the lower tiers of the base. Stop ramming materials as soon as the surface becomes even.

Backfilling of the supporting base is started with gravel of the required thickness, while the material is distributed evenly over the area. The next step is backfilling with sand about ten centimeters thick. Each layer is poured with water and carefully rammed. Finally, crushed stone is used and treated in the same way as with the lower tiers of the base. Stop ramming materials as soon as the surface becomes even.

Laying hydro and thermal insulation

The use of waterproofing is an integral step in laying the foundation. With it, moisture resistance of the house is ensured and an increase in service life. For insulation in houses, a polyethylene film is used, which is laid in several layers. The joints are connected with adhesive tape or tape on an adhesive basis. Next, a heat-insulating layer is applied, which will make the flooring of private houses warmer. Thermal insulation is done using mineral wool, polystyrene foam, expanded clay and polyurethane foam.

Reinforcement

In private houses, concrete floor reinforcement is used, which is necessary to increase structural strength and resistance to heavy loads. For reinforcement, a special plastic mesh or wire product is used. For convenient pouring, formwork is used, which is made of boards or plywood.

Maps, beacons for pouring the floor

To fix the beacons when pouring the floor, it is better to use diluted building gypsum, spreading it out in several piles and drowning the substrate in gypsum.

To fix the beacons when pouring the floor, it is better to use diluted building gypsum, spreading it out in several piles and drowning the substrate in gypsum. Beacons applied to the floor are needed to give the required evenness. Lighthouses can be made of a square profile, a wooden block or a round pipe. Before installing this design, the room of a private house is divided into equal segments. Lighthouses are installed on pieces of concrete mortar. To make it easier to remove them from the mixture in the future, the guides are lubricated with oil or special treatment. In this case, you need to constantly monitor the position of the beacons, which should be horizontal.

A private house with large floor dimensions will require a breakdown of the room into maps, the use of which is relevant if it is not possible to fill the entire room at once. After the territory has been divided into sections, formwork is constructed with a height equal to the zero point line.

Solution preparation

To prepare the correct solution for pouring, it is recommended to use a concrete mixer. The solution is prepared according to the following recipe: 2 buckets of perlite, which is necessary for better thermal insulation of the house, are immersed in a concrete mixer and a bucket of water is added. Then you need to mix thoroughly and gradually pour a bucket of sand, pour the mixture with two liters of water and mix until a loose consistency. Next, the solution is allowed to "rest" and continue to knead until a plastic state. When dealing with a private house, it is recommended to use cement marked M500 and M400 for pouring the floor.

Pouring and leveling concrete mix

Pneumatic blower for semi-dry screed.

Pneumatic blower for semi-dry screed. To properly apply the coating, we prepare the floor for pouring in a private house. To do this, at the end of the construction, we remove all debris and leave the working object clean. After preparing the concrete solution, we begin pouring from the door on the opposite side. When applying the mixture, holes are made in it to remove air bubbles.

Using the rule, we level the solution, after removing it, fill the resulting space with a new mixture. The strength of concrete is reached in about a month.

Leveling screed

Even when working correctly with the fill, the surface is not always smooth; for this, they are used, which are purchased in hardware stores. After their application, the formed air bubbles are removed and the concrete is allowed to dry for 7-10 days.

conclusions

Having a private structure, you can do the flooring with your own hands. The main thing is to choose the right materials and complete all the steps in the process. Then the floors of a private house will last more than one year.