For low grillages and strip foundations, the installation of a concrete floor on the ground allows you to save the construction budget and get rid of the underground, harmful radon emissions. The floor on the ground is a rough screed, it cannot serve as a finishing layer, it requires decoration with floor coverings. But in the pie of this design, insulation and waterproofing are laid, operating costs for heating are reduced, and the operational life of the building is increased.

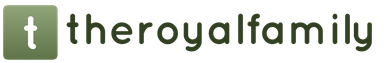

The cheapest lower level option after the earth floor, which is currently not used anywhere, is the floor on the ground. The building codes SP 31-105 indicate the installation of floors on the ground with three minimum layers:

- crushed stone bedding with a minimum thickness of 10 cm;

- polyethylene film 0.15 mm;

- concrete slab with a minimum thickness of 10 cm.

To ensure the mobility of the structure, the junction with the wall is organized through a damper layer, which solves several problems:

- damping of vibrations and structural noise;

- lack of a rigid connection with the elements of the foundation or basement to avoid destruction;

- providing an air gap to compensate for the linear expansion of the material.

During possible subsidence and swelling of the base soils, the floor slab moves freely along the ground in a vertical level without destroying the plinth, grillage or MZLF.

The need for the remaining layers of the floor cake on the ground is due to the improvement in the performance of the structure:

- footing - a screed of lean (B7.5) concrete to ensure a flat surface when laying rolled waterproofing and sealing joints, protecting the material from multiple punctures with sharp edges of crushed stone;

- thermal insulation - a carpet made of extruded high-density polystyrene foam allows you to keep the heat of the bowels under the building, due to this, completely get rid of frost swelling, increase the operational life of the foundation and reduce heat loss in the floors;

- reinforcing belt - perceives tensile loads in the lower level of the screed;

- underfloor heating contours - increase the comfort of living, reduce heating costs.

Important! When using wire mesh to reinforce the screed and the contours of the warm floor, it is necessary to increase the thickness of the structure - the diameter of the pipes + 2 cm.

Assignment of the floor on the ground

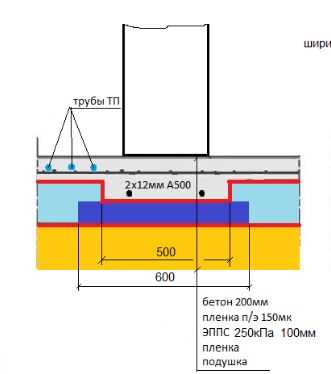

A concrete screed is necessary to provide a rigid base when installing floor coverings. This slab is not a supporting structure; it is forbidden to support stoves, stairs and partitions on the floor on the ground. However, the manufacture of a foundation under internal non-bearing walls is expensive, so the following technology is used:

- a stiffening rib is made under the partition along the entire length;

- a gap is created in the upper layer of insulation, into which a reinforcing cage is laid, connected to the floor grid along the ground.

Floor stiffener on the ground under the partition.

Important! This option is not suitable for supporting internal stairs made of reinforced concrete, rolled steel.

In baths and showers, the screed allows you to create slopes for gravity removal of drains. In other ways, it is more difficult and expensive to do this.

Manufacturing technology

Before pouring the floor on the ground, it is necessary to prepare the base and lay all the layers of the structure. It is advisable to lay the mixture in one go, use beacons and a fine fraction of concrete filler.

Underlayment

Before pouring the floor in the premises of the dwelling, one should take into account the nuances of the base soils:

- despite the fact that the floors on the ground are made of concrete of class B12 and higher, they are easily destroyed when the soil shrinks under them, so the fertile layer should be removed completely;

- the underlying layer of non-metallic material must be compacted in layers of 15 cm maximum with a vibrating plate or manual rammer;

- sand has capillary absorption of soil water, it is used only at low GWL from 1.5 m;

- crushed stone can be used on wet soil, since capillary rise is not possible in this material.

To reduce the construction budget and improve the quality of living, it is important at the initial stage to plan the level of the floor on the ground in all rooms of the building, taking into account the requirements:

- the step near the front door is extremely inconvenient to use, the flooring should be on the same level as the threshold;

- it is forbidden to rest the screed on the elements of the plinth or foundation protruding relative to the internal walls;

- when compacting sand, it is forbidden to spill it with water; a layer of watering can should be moistened.

Advice! With a limited budget, you can do without footing by leveling the crushed stone layer with sand. In this case, the film, membrane or rolled waterproofing will not be torn by rubble stones. However, the surface of the underlying layer in this case must be shed with cement milk to form a crust, for the convenience of sealing the waterproofing joints.

Underlayment and waterproofing

The main requirement for a waterproofing layer is its continuity. Therefore, problems arise:

- rolled bituminous materials (Bikrost, TechnoNIKOL) and polymer films are difficult to lay on the ground properly, since when walking on them, the joints diverge in the future;

- heavy EPDM membranes have a large format, fit without joints, but are very expensive.

Therefore, at first, a footing 5–10 cm thick is poured, providing a rigid, even base for gluing a plastic film or fusing bituminous material.

![]()

Important! The footing is also forbidden to be rigidly connected to the elements of the foundation or basement. This layer does not need to be reinforced; lean concrete with a minimum cement content can be used.

It is not enough to know how to make a floor on the ground correctly, it is important to place the layers of the construction pie relative to each other in the right order:

- many individual developers lay insulation on the footing or on the underlying layer and cover it with waterproofing from above;

- or duplicate the film under the insulation and on top of it, increasing the cost of the construction budget.

Both options do not provide any advantages, since the membrane, film or roll material must prevent the extruded polystyrene foam and the top screed from getting wet with soil moisture, which can also be in a vapor state.

Under normal conditions (permanent heating), the temperature under the concrete slab and insulation is always lower than in the room. Therefore, the penetration of excessively humid air from the room into the floor along the ground is impossible according to the laws of physics. Vapor barrier inside this structure is not needed and even harmful.

Important! Bituminous roll materials are welded onto the footing in two layers with an overlap of 15 cm at least perpendicular to each other. Films are glued in two layers in any direction. The EPDM membrane is mounted in one layer.

More details: .

Insulation and damper layer

The floor on the ground performs the functions of an overlap, but does not have a rigid pinch along the perimeter. Therefore, the insulating properties of this technology are by default higher than in joist slabs and for PB, PC slabs:

- the lower layer of insulation reduces or completely eliminates heat loss at the junction points with the base;

- the floating screed is cut off from the walls with a damper layer, structural noise and vibration are not transmitted to the room;

- the quality of the concrete surface is higher than that of the slabs, there is no need for grouting and leveling screed;

- there is no underground, respectively, and harmful accumulations of radon gas from the ground;

Important! The damper layer is usually a special tape or strips of expanded polystyrene. Tape pasted over the perimeter of the base or foundation. Insulation strips are installed on the edge close to the walls along the entire height of the screed cake, starting from the sole of the footing.

The thickness of the heat-insulating material depends on the region of operation, it is 5 - 15 cm. Expanded polystyrene plates are laid apart, the joints are filled with mounting foam.

Communications and reinforcement

The floor on the ground built according to the specified technology is a floating slab. Therefore, before laying the mixture, it is necessary to bring into the premises risers of engineering systems - heating, cold water / hot water, sewerage. Electricity and gas lines are separated at the finishing stage, grounding - depending on the specific building project.

Advice! The maintainability of communication input nodes is zero by default. Therefore, it is increased by laying risers inside pipes of larger diameter, from which, if necessary, a clogged sewer or a rusted water supply pipe can be pulled out for replacement without destroying the screed.

In order for a warm floor made on its own to have a margin of safety in case of possible redevelopment, the structure is often reinforced in the lower third. For this, wire meshes Vr, corresponding to GOST 6727, produced in rolls and cards, are optimally suited.

Reinforcement is made in one layer, the overlap is at least one cell, meshes are laid to provide a lower protective layer on concrete or plastic gaskets.

Mixing and concrete care

The best option is to concret the screed in one step with a mixture that is made at the factory and delivered to the building site by a mixer. The main difficulty when laying concrete is the impossibility of walking on a wire mesh. Therefore, fill options are applied:

- ladders - in the cells of the grid, gaskets suitable for the format are installed (pieces of brick, pieces of timber), on which the boards rest, as they move, they are rearranged to a new place;

- “paths” - since the pouring starts from the corners farthest from the doorway, concrete is poured in the direction of the master to the workplace, the mesh inside the concrete receives the necessary rigidity, you can walk along the resulting paths without mixing reinforcement in neighboring areas.

The installation of beacons increases the productivity and quality of the screed. Depending on the thickness of the layer, plaster beacons or a profile for GKL systems are used.

Important! If the project includes a warm floor, its contours are laid on top of the wire mesh before pouring. In this case, the thickness of the screed automatically increases. You can turn on the heating only after the strength of the structural material is 70%.

Technology nuances

According to the technology, partitions must be based on their own foundation. For flights of stairs and heavy heating appliances, slabs or grillages are poured on piles. However, individual developers often violate these technologies by erecting light partitions on the floors on the ground. In this case, the structure should be reinforced in advance with stiffeners towards the ground:

- in places where the partition passes, a gap is created in the insulation;

- a reinforcing cage is installed in the resulting cavity by analogy with a strip foundation.

If the thickness of the heat-insulating layer is insufficient, the base under the stiffening rib is additionally deepened by 20 - 40 cm. This allows you to ensure the continuity of the insulation layer and eliminate cold bridges.

Thus, the ground floor budget can be adjusted at the design stage depending on available funds and geological conditions. All works are available for self-execution for a home master with minimal construction experience.

Advice! If you need repairmen, there is a very convenient service for their selection. Just send in the form below a detailed description of the work to be done and you will receive offers with prices from construction teams and firms by mail. You can see reviews of each of them and photos with examples of work. It's FREE and there's no obligation.