One of the main structural elements of the building are floors. Much depends on their competent installation, including the hygiene and reliability of the house, the comfort of living in it and the durability of the outdoor coating. The flooring device in a private house - the procedure is quite time-consuming, which is the fifth of the general labor in the construction of the construction as a whole. And in the material plan, the installation of floors occupies almost a third of the cost of construction work. This alignment refers not only to the capital residential structure, but also to the country.

The floor is the most wearing structure, as it is subjected to a constant effects of mechanical and abrasive loads, so it is necessary to approach its device. It should be not forgotten that the unfailed design of the floor will result in rapid wear and further repair or replacement of even the most expensive flooring.

Floor floors

The floor is a multi-layer design, and not just a coating, as some of them imagine. It is placed on the overlap or directly on the ground, which depends on the designation of the room and approaching the groundwater. The floor of the first floor differs in its design in that it is mandatory in its "pie", it is mandatory, heat and waterproofing are included, and between the floors laid a layer of soundproofing material. The floors in the garage or basement also have their own characteristics. It is important that the base withstand the calculated loads and did not allow moisture penetration from the soil.

The components of the floor suitable in private household or a summer house are conditionally divided:

- On the finishing floors - flooring.

- Black, or rough floors - a durable smooth base of one or more layers, intended for clean floor flooring.

Also part of the floor includes:

- waterproofing;

- thermal insulation;

- aligning screed;

- sound or noise insulation.

The floor design of the first floor can be:

- The connected - the screed with a concrete base is a single whole.

- On the dividing layer - the screed and the surface of the base are not related to each other.

- Floating - all layers are separated not only from the base, but also from the walls.

Floors must comply with certain requirements:

- strength;

- thermal insulation;

- silent;

- anti-skid;

- hygienicness;

- fire safety.

There are several options with which you can make a high-quality and beautiful floor in the house. It can be a single mackerel design that is most suitable for the dacha mounting. In a residential building, a double wooden or concrete floor with good insulation is more common.

Single design from boards

The simplest and most affordable method of aging of the board are widely used in the country, which is not provided to visit during the cold season. Also, a single wooden floor of a residential building is appropriate in the warm regions of the country.

Boards are laid in two ways:

- on the lags located over the beams close to the walls;

- on the beams installed on the support pillars.

From the thickness of the boards directly depends on the step of the lag or beams. The thinner the board, the less distance.Lags and support beams are set up by level, correcting their position horizontally with wooden wedges. After that, the boards nail to the carrier elements are nails.

Double design from boards

Warming and arrangement of the first floor

The flooring device at the cottage or in a private house in this case is more difficult and long, but the design itself provides for a significant reduction in heat loss. Its feature is a black floor device. Experts recommend using for this inexpensive coniferous wood, and to create a wooden finishing coating, apply tipped boards.

Between the two levels of the floors, the thermal insulation layer of foam, slag, dry sand, ceramzite concrete or expanded polystyrene was placed. In the country, it is advisable to use the mixture of clay, straw and wood sawdust. An indispensable condition in a wooden house-building is a small clearance device over thermal insulation and a clean floor for air layer.

Concrete floor

The device of the low-floor concrete floor is reduced to several stages:

- Applying markup with a laser.

- Failure, leveling and tamping of the rubble or clay layer. As well as the device and smoking the sand layer with a periodic watering and a punch.

- Flooring waterproofing from a polyethylene film with a wall at the walls above the level of the future concrete floor.

- Installation of guides for beacons in accordance with previously made markups.

- Pouring a concrete solution to the required level and recalling by its rule.

After setting the concrete solution, the guides are carried out, and the voids are poured with a mixture of concrete, after which they drag. Next, it remains only to cover the surface with polyethylene and from time to time to moisten it with water. The period of complete secretion of the concrete solution is 20-30 days depending on the temperature and the level of ambient humidity.

Device of black floor

Flooring device in wooden houses

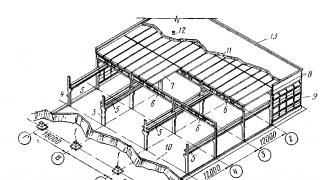

The main purpose of the black floor is the distribution of loads and leveling the base under the device of the floor covering. The classic option for a private house is the laying of logging on the basic base after a certain distance between themselves. When working on large areas, a crate consisting of double frames is mounted for better stiffness. In this case, transverse rigels are laid between lags.

In the lower part of the lag on both sides, the bars of 50 × 50 mm are fixed and fixed by a black floor of a chipboard, an OSB, an umbered board, a hill or plywood, with subsequent fastening of them on a wooden bar brazed. This design is good because it allows for intervals between lags to lay the insulation and the waterproofing layer.

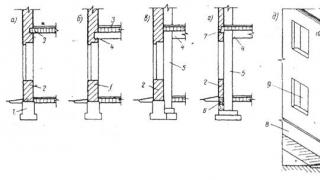

The black floor device in the house starts from the equipment of the ventilation space under it. For this, in the opposite corners of the foundation, there are no more than 10 × 10 cm holes in advance, which are then covered with lattices. Their number and location depends on the area of \u200b\u200bthe house.

Also produce wood processing of all components of roughing with antiseptic solutions. Such events allow to extend the life of black sex and lag. The ends of the lag are proclaimed without affecting the ends, or turn them into their rubberoid. In order to maximize the various knocks and stons, use noise absorbing gaskets.

Concrete or metal structures close in walls or poles installed on the walls can be used as supporting beams (lag).

Paul in soil

The cheapest option is the first floor of the ground floor. But they are not recommended to do in the house, which is not used in winter. After all, without internal heating, the ground during this period can freeze, and subsequently seek. It is also unacceptable to make such structures in the event that the level of groundwater rises into the unfavorable season too high.

There are two options for the flooring devices directly on the ground, which can be used both in the country and in a private house:

- Monolithic, suitable for warm climatic zones, as well as for basements or hozpostroops.

- With the underground that meets the requirements provided for in private house-building.

Monolithic floor

Communicative device of concrete floor

The most simple of all the well-known technologies of the floor slab in a private house includes several stages:

- removing the layer of maternal soil of the minimum thickness of 300 mm;

- the device of a sand pillow with layer-grass traam;

- laying of waterproofing in the form of a small layer of oily clay or two layers of a rolled backruer with bitumen impregnation;

- failure of rubble, impregnated with bitumen;

- device of the intermediate layer of concrete and cement screed;

- installation of floor tiles, linoleum or boardwalk, stacked by lags installed on the rubberoid layer.

If necessary, protection from surface atmospheric waters is also performed by device of the drainage system.

According to the technology of the lower layer of the floor inside the perimeter of the building, for the possibility of a first floor device, it should be above the outdoor layout of the soil at a distance of at least 10-15 cm. As a heater, it is allowed to use 8-12 centimeter plates of high-blooded polystyrene foam, bonded among themselves.

Wooden floor with underground

According to the planned area, they link the level of the soil level to the necessary depth, make a sandy pillow, and the crushed stone is poured on top along with gravel, grieving them into the base. Then the layer of oily clay is placed as waterproofing and throw the entire area with hawed lime, and then slag or rubble.

At the next stage of work for lags, the support columns from burnt bricks in a step of 1 meter in two rows and more are installed. On the poles lay 1-2 layers of rubberoid, impregnated with antiseptic cuts of boards and lags, along which the headboards are laid.

In the case of a device of a double wooden insulated floor, it is also mounted and the black flooring, which consistently stacked hydro, heat and vaporizolation. Only after that the floorboards are mounted.

Conclusion

The variants of the insulated floor device for the first floor are many, but the basic principles remain unchanged. The flooring device in a private house can be floating or with adjustable lags, enjoyable comfort and the component of a single integer with the base. Each house in its own way is unique, therefore the floor is done on individual calculations and drawings depending on the ground conditions, species of materials, the size of the construction and other important factors.

Ruslan Vasilyev

Ruslan Vasilyev