The elimination of "wet" processes accelerates and simplifies construction. It is not surprising that, after the emergence of the relevant technologies, there was a challenged attention to the profile specialists. But not only professionals are interested in a dry band screed: price, pros and cons, expert reviews. These knowledge will be useful to any real estate owners. They will help them make the right decisions when choosing a suitable technique for radical reconstruction, capital repairs, the construction of new buildings.

For the correct understanding of the advantages of the new methodology, it is necessary to clarify the shortcomings of old technologies. The starting materials for the concrete screed have a significant weight. Their transportation on the object, loading and unloading operations are accompanied by large labor costs.

To prepare a mixture of sand and cement, there will be significant physical efforts. It is recommended to pour the screed in the room in one working day. This will provide the same structure parameters and good consumer characteristics of the layer. To fulfill such a condition, you have to purchase or rent a concrete mixer, a vibrational installation, other special equipment.

The presence of water in solution implies the need to bottom with reliable. Full layer frozen occurs in 25 - 30 days. Only after this period you can install finish coatings, start exploitation. During drying, it is necessary to maintain a favorable temperature and. Stacking a concrete screed is not performed in frosty conditions.

Meanwhile, damage, pipeline cannot be excluded. If there is a dry band screed, pros and cons, reviews, price, you need to remember about the simplicity of dismantling. It can be done independently, without unnecessary noise and contamination, with the use of primary tools. Permissible reuse of some materials.

Main parameters of the methodology

The above disadvantages are eliminated partially, or completely using the next design.

In this figure, a typical distribution of layers is depicted when installing a dry band screed in an apartment:

- The reinforced concrete plate of the inter-storey overlap is closed with a film to prevent flow of refrigeration.

- The edge tape in this case does not so much compensate for the thermal expansion, as when laying a "wet" screed. It also does not miss water that worsens the insulation properties of the backfill.

- Next follows the main layer. It is formed from solid granular materials.

- In this embodiment, two coatings of gypsum-fiber plates are used. This solution strengthens the basis. Therefore, on top without restrictions, you can install linoleum, laminate, other types of finish coatings.

Article on the topic:

Do you want to refresh the floor in your dwelling? Have you chosen laminate for these purposes? If so, then laying a laminate with your own hands (step-by-step video instruction at the end), which is described in this article for you.

Already at this stage, without a detailed study of the installation, you can make preliminary conclusions about the advantages of the technology of the device of a dry band tie:

- For installation, you can use lightweight materials. They are not difficult to move.

- It is permissible to perform work on a temporary schedule convenient for a particular person. Delays in filling filler will not worsen the final consumer characteristics of the layer.

- Working operations are quite forces to one person. You will not need to buy expensive equipment, studying complex technologies.

- After laying, such a screed is ready to immediately apply in accordance with the target purpose. If it is necessary to bind drying plates with glue, it does not take it over a few hours.

- Created design can be disassembled, upgraded without excessive costs.

But this is not a "one-time" acquisition. Such universal technique will come in handy in the future for fastening the floor boards, solving other practical tasks

Important! You should not forget about the hygroscopic of frighting. If a long break had to do, it is necessary to provide a low level of humidity in the room.

Material overview

As a backfill, the grainsite is well suited for a dry tie. Its price is low, so even on large objects it will be possible to exclude excessive costs. In this design, not standard, but chopped to 5-6 mm granules are used. This porous material is created from burnt clay. It is environmentally safe, no allergens and other hazardous substances. Its beneficial properties are preserved for decades in constant condition. Such a porous material creates a layer with excellent sound and thermal insulation characteristics.

Vermikulite is a material created by nature during the weathered of mica rocks. It is burned to eliminate moisture and creating a plurality of pores. In the heating process, the initial dimensions increase more than 12 times, the insulation parameters are improved.

Such a filler is resistant to various types of external influences. It is not able to spoil even acids and other potent chemical compounds. Vermikulite is used to frown firewalls. It should be borne in mind that it absorbs moisture very well, so when installing it is necessary to use the corresponding protective layers.

Another popular filler, perlite, is created from mountain volcanic rocks. It is removed by moisture with heat treatment. This material is chemically inert, safe. It has excellent insulating characteristics, resistance to high temperatures.

The following table marked features of materials for the top layers of the screed.

| Picture | Name / abbreviation | Benefits | disadvantages |

| Strength, low cost, uniform structure, good insulating characteristics. | Relatively large weight, complexity of machining. | |

| / G. | Cheap, lightweight material. | Low strength, ability to absorb water. |

| Hypracolocone sheet / GVL | Low weight, improved strength due to the presence in the structure of the fibers, some modifications have resistance to moisture. | The modifications not absorbing water cost more than standard products. Strength is less than that. |

| Plywood | High strength, environmental cleanliness. | The formation of deformations and damage to the structure of moisture absorbing, high cost. |

| Plates of polystyrene foam | Low weight, resistance to moisture, excellent insulation characteristics. | Only at high density is ensured by the strength for floor coatings. |

Opinions of specialists

To find out the pros and cons of the dry band screed, it is necessary to learn from among the prices of the reviews of professionals. Below are the appropriate recommendations that apply to the choice of materials and the application of technology in practice.

The fading listed above quickly absorb moisture, which worsens their insulation characteristics. You should buy vertimiculitis only from responsible sellers. Insufficiently high-quality material may contain asbestos impurities that better exclude from structures in residential premises.

It is falling asleep neatly. The room closes the doors and windows to exclude drafts. It is less durable compared to vermiculitis. The upper layers are recommended to be created using rigid plates providing protection against mechanical effects.

All modern materials created from wood waste (chips, fibers) are better to oppose high humidity compared to the source natural material. If selected, it is necessary to purchase a product in a special, resistant water, execution.

Such materials create additional insulation. To ensure resistance to mechanical loads, you need to select the plates with a density of 35-40 kg per m. Cube. It should be noted that the total thickness of the layers will increase. Such a solution is used only with a sufficient height of the ceilings indoors.

Installation of dry floor screed with your own hands: video, photo, written instructions

In this video, you can explore the process of creating a multilayer coating.

| Picture | Algorithm |

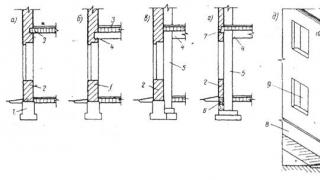

| Old floor covering is removed up to concrete overlap. Remove the construction trash, plaster. Close up cracks, eliminate other defects. | |

| Align the perfect surface is not necessary, because it is for this that the screed is installed. However, it is necessary to remove acute protruding parts capable of damaging waterproofing. |

| By the contour of the room establishes damper tape. In order for the factory product with the adhesive layer, it is securely joined, you should pre-align the bottom of the wall, clean it from contaminants. |

| Covered the entire surface of the base with a thick polyethylene film. In the fields of joints use tape, two layers of the mustache to ensure good tightness. |

| Align bulk materials are convenient with such devices. Aluminum guides are installed with a level horizontal control. |

| So that GVL, or other gypsum plates provided sufficient strength, they are mounted in two layers. The joints are shifted. Fixation is performed by adhesive composition and screws. |

| When using polystyrene foam with sufficient density, you can use only one row of plates. They are installed in a checker. It is beneficial to use on a flat surface (without partitions) products with lock connections on the ends. If you fill the joints with scotch additionally, additional protection of the moisture filler will be created. |

| The plates of polystyrene are installed a damper gasket on which the laminate is placed. |

For your information! These descriptions are seen that the price of dry mixes for a screed of a floor is only one of the costs of costs. The final value is calculated taking into account all the components of a specific project.

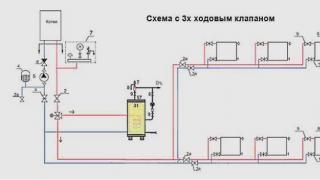

Separately, it is necessary to study the features of using such technology together with the installation of the heating system.

When the pipeline is installed inside a classic concrete screed, it performs its functions effectively. Bulk fillers create a barrier to the spread of heat, increase inertia.

Is the dry band screed profitable: the price per square meter and other conclusions

The relatively high price of the dry band of the floor KNAUF is explained by reliable warranty obligations of a solid brand. In this case, the manufacturer ensures the unity of technical parameters in each commodity lot, the absence of impurities harmful to health. It is convenient to work with similar materials.

However, a deeper study allows us to find out that there are no special components in the composition. An ordinary clay is used. Its use is offered on the same technologies described in this article. Thus, if you consider all the above recommendations, you can independently optimize the cost of the dry floor screed.