building elements

The building consists of a certain number of interconnected elements that perform their function

Bearing structures

Structural elements of a building or structure that perceive the main loads (wind pressure, weight of snow, people in the building, equipment, soil pressure on the underground parts of the building, etc.). By the nature of these loads, load-bearing structures are distinguished: individual supports working in compression (columns), foundations, walls, load-bearing wall panels, etc.); working mainly in bending (panels and floor beams, truss and bridge trusses, frame crossbars, etc.); working mainly in tension (membranes, guys, hangers, braces, etc.). Depending on the geometric shape of the load-bearing structures. subdivided into linear (beams, columns, rod systems); planar (slabs, panels, floorings); spatial (shells, vaults, three-dimensional elements). The load-bearing structures of a building (structure) together form its supporting frame, which must ensure the spatial immutability, strength, rigidity and stability of the building (structure).

Walling

They serve to protect the building from atmospheric pressure. Separate rooms from one another. Provides a standard microclimate in the room: temperature, humidity level, acoustic mode.

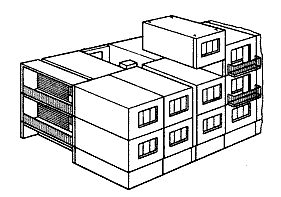

The internal space of buildings is most often divided into separate rooms - parts of the internal volume of the building, fenced on all sides. The totality of all such rooms, the floors of which are located on the same level, forms the floor of the building. Individual floors have a specific name (Fig. 1.1).

Basement - a floor completely or mostly buried in the ground (also called "basement floor") (a). Semi-basement, or basement - floor, the floor level of which is buried from the level of the sidewalk or blind area by no more than half the height of the room (b).

Aboveground - floor (first, second, third, etc.), located above ground level (b, c).

Attic (or attic) - the floor located between the roof and the ceiling above the last floor of the building (the so-called "attic floor") (d). Attic (or attic) - floor, Fig. 1.1. The location of the floors of buildings fenced off inside the attic space formed by a pitched roof, and designed to accommodate residential or auxiliary heated premises; the area of the horizontal part of the ceiling is desirable to occupy at least 50% of the floor area, and the height of the walls to the bottom of the sloping part of the ceiling is different, depending on the angle of the roof (usually not less than 1.4-1.m).

Technical - the floor intended for placement of the engineering equipment and laying of communications. It can be located in the lower (technical underground), upper (technical attic) or in the middle part of the building, as well as above driveways, above the first public floor of a residential building, etc.; in industrial buildings, the need and location of technical floors are determined mainly by the requirements of the technological process. The height of the technical floors depends on the type of equipment and communications, taking into account the operating conditions.

All these and other premises are elements of the space-planning structure of the building. The material shell of the building is made up of interconnected structural elements - independent parts or elements of the building, each of which has its own specific purpose: walls, foundations, roofs, etc. (Fig. 1.2). Structural elements are either made up of smaller, prefabricated elements - building products delivered to the construction site in finished form (prefabricated slabs, steps, roofing products, etc.), or erected on site from building materials,

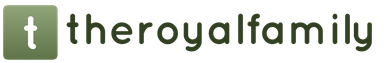

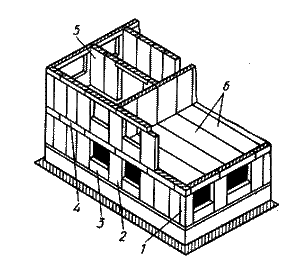

Rice. 1.2. The main elements of buildings:

a - old building; b - frame-panel modern; c - from bulk blocks: 1 - foundation; 2 - base; 3 - bearing longitudinal walls; 4 - interfloor floors; 5 - partitions; 6 - roof rafters; 7 - roof; 8 - staircase; 9 - attic floor; 10 - crossbars and frame columns; 11 - hinged wall panels; 12 - piles; 13-15 - three-dimensional blocks (13 - rooms; 14 - bathrooms and kitchens; 15 - staircase); 16 - blind area.

Non-force impacts: atmospheric precipitation; heat and moisture flows, impacts caused by temperature differences or potential differences in humidity of outdoor and indoor air; noise and vibration coming from outside or from adjacent premises or caused by the operation of engineering equipment; air infiltration through leaks, etc.

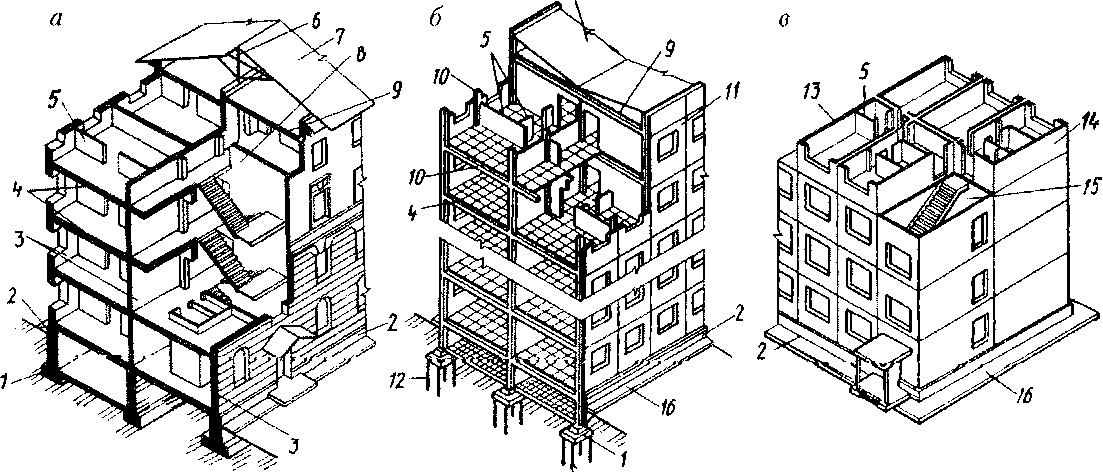

1 - foundation, 2 - basement floor; Z - ceiling over the basement; 4 - waterproofing; 5 - outer walls; 6 - interfloor floors; 7 - internal walls; 8 - partitions; 9 - attic floor; 10 - attic; 11 - roof; 12 - stairs; 13 - parapet; 14 - windows; 15 - blind area.

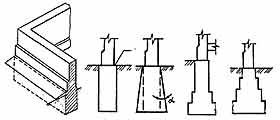

The foundation is a supporting part through which the load is transferred from the building to the ground - the foundation. The base is called natural when the soil under the base of the foundation is in a state of its natural occurrence; if the soil is previously artificially strengthened, then this is called artificial. Foundations are exposed to groundwater, often aggressive, and variable temperatures, therefore, materials with high strength, water and frost resistance are used for the construction of foundations: reinforced concrete, concrete, rubble stone. In mass construction, the foundations for the walls of buildings are, as a rule, prefabricated: from reinforced concrete slabs and blocks. Usually, foundations with a flat sole are divided into strip foundations, which are laid under walls, or column foundations - in the form of rectangular, trapezoidal and other types of separate supports for free-standing columns or pillars. There are also pile foundations, when the building rests on wooden concrete or reinforced concrete piles immersed in the ground.

Walls according to their purpose and location in the building are divided into external and internal. External walls 5 (Fig. 1) protect the premises from the external environment and protect them from atmospheric influences, internal 7 - separate one room from the other. Both external and internal walls perceive wind loads on the building, provide sound and heat insulation of the premises, protect them from external climatic influences.

Walls are load-bearing, self-supporting and non-bearing. Bearing walls both perceive and transfer loads to foundations not only from their own weight, but also from other structures (ceilings, roofs, stairs), as well as wind loads.

Self-supporting walls transfer loads to the foundations only from their own weight. Floors or other building structures do not rest on such walls.

Walls that only enclose the premises of buildings from the outside and transfer their own weight within each floor to other load-bearing structures are called non-load-bearing. The same walls, hung on the vertical structures of the frame of the building, are commonly called hinged.

The upper part of the outer wall, protruding beyond the plane of the wall, is called the cornice. The removal of the cornice, i.e., the distance from the wall to the edge of the cornice is assigned according to the project. At the same time, the need to protect the walls from water flowing from the roof, and the architectural features of the building, are taken into account. Buildings with walls without a cornice have a parapet 13, which is the enclosing part of the roof.

Interfloor floors 6 combine enclosing and load-bearing functions and divide the building in height into floors. Ceilings 9 above the upper floor are attic. Ceilings in stone buildings are made of prefabricated reinforced concrete panels, in low-rise buildings - sometimes from wooden beams, to which ceiling parts made of plywood, chipboard or plasterboard are attached.

Partitions 8 - enclosing elements that divide the interior of the building within one floor into separate rooms, are built from gypsum, fiberboard, ceramic and other hollow stones, bricks and other materials. Partitions are supported by ceilings and their own weight is transferred to them.

Roof 11 combines enclosing and load-bearing functions and serves to protect the building from atmospheric precipitation and remove them outside; consists of reinforced concrete panels resting on the outer and inner walls and laid with a slope to organize drainage. A space is formed between the roof panels and attic floors, which is called attic 10. In low-rise buildings, the roof is made of wooden rafters, along which a crate is made of boards, to which a roofing of asbestos-cement and other sheets or roofing iron is attached.

Stairs 12 serve to communicate between floors; located in rooms with load-bearing walls (stairwells). The part of the stairs between the platforms is called the march. In stairwells, as a rule, elevators are also placed.

Structural schemes of buildings. The main load-bearing elements (foundations, walls, etc.) together form the building's load-bearing frame, which perceives all loads acting on the building and transfers them to the foundation, and also ensures the spatial immutability (rigidity) and stability of the building.

According to the structural scheme of the supporting frame, the buildings are divided into frameless, framed and with an incomplete frame. In frameless buildings, walls serve as the main vertical bearing elements, in frame buildings - individual supports (columns, pillars), in buildings with an incomplete frame - both walls and individual supports.

Residential and public buildings, as a rule, are built of brick, ceramic or concrete stones and small blocks, as well as large-sized parts and elements - large-block, large-panel and volume-block.

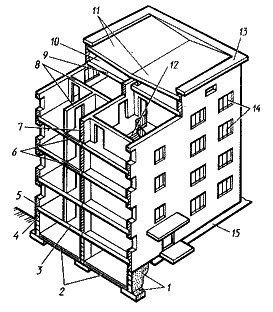

Frameless buildings made of bricks and small stones and blocks are usually erected with longitudinal load-bearing (Fig. 2, a) external and internal walls. Transverse walls in such buildings are arranged mainly in stairwells, in places where smoke and ventilation ducts pass, as well as in the spaces between them to give greater stability to the longitudinal walls and buildings as a whole. In buildings with transverse load-bearing walls (Fig. 2, b), the longitudinal outer walls are self-supporting, and the ceilings rest on the transverse walls. Frameless buildings are also being erected, in which both transverse and longitudinal walls are load-bearing. In such buildings, floor panels the size of a room rest on all four sides on transverse and longitudinal walls.

Fig.2. Structural schemes of frameless buildings with load-bearing walls

a - longitudinal, b - transverse.

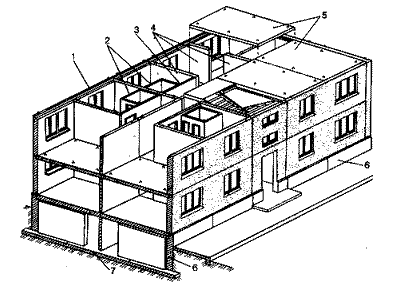

Fig.3. Structural scheme of a large-block building with transverse and longitudinal load-bearing walls

1 - corner block; 2 - parietal; Z - window sill; 4 - jumper; 5 - block of the inner wall; 6 - floor panels.

Frameless large-block buildings with walls made of concrete and other blocks have structural schemes with transverse and longitudinal load-bearing walls (Fig. 3). Public high-rise buildings are often erected with longitudinal load-bearing walls. At the same time, depending on the width of the building, there can be not one, but two internal longitudinal walls.

Frameless large-panel buildings are: with three longitudinal load-bearing walls: with transverse load-bearing walls-partitions, installed with a small or large step (distance) from each other.

In houses with transverse load-bearing partition walls (Fig. 4), all the main elements are load-bearing: transverse partition walls, internal longitudinal and external walls. Floor panels are supported on four sides. In this case, the outer wall panels 1, which differ little from the outer panels in houses with longitudinal load-bearing walls, are also considered load-bearing. Partition panels 4 and panels of the inner longitudinal wall in such houses are made of heavy (structural) concrete. Exterior wall panels are made of lightweight concrete or three-layer: heavy concrete with heat-insulating liners.

Fig.4. Structural scheme of a large-panel house with load-bearing partition walls

1 - external wall panels; 2 - sanitary cabins; Z - load-bearing partitions; 4 - internal load-bearing transverse walls (partitions); 5 - floor panels; 6 - plinth panels; 7 - foundation blocks.

Frame buildings

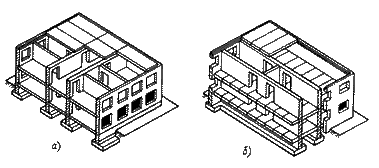

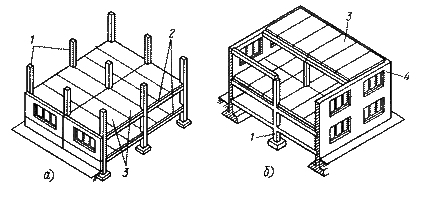

Frame build, as a rule, public and administrative buildings. In recent years, frame multi-storey residential buildings have also been built. In buildings with a full frame (Fig. 5, a), the supporting frame consists of columns and crossbars, made in the form of beams for supporting floor structures. Columns and crossbars fastened together form load-bearing frames that perceive the vertical and horizontal loads of the building. External walls in buildings of this type are hinged or self-supporting. Curtain curtain walls in the form of curtain panels are attached to the outer columns of the frame. Self-supporting exterior walls rest directly on foundations or on foundation beams installed on column foundations. Self-supporting walls are attached to the frame columns.

Fig.5. Structural scheme of buildings

a - with a full frame; b - with an incomplete frame; 1 - columns; 2 - crossbars; H - floor panels; 4 - load-bearing outer walls.

In buildings with an incomplete frame, the outer walls are made load-bearing, and the columns are placed only along the internal axes of the building. In this case, the crossbars are laid between the columns, and sometimes between the columns and the outer walls. Such a constructive type of building (Fig. 5, b) in modern construction is of limited use.

A building of any type must not only be strong enough: not collapse under the action of loads, but also have the ability to resist tipping under the action of horizontal loads, and have spatial rigidity, i.e., the ability, both as a whole and in its individual parts, to maintain its original shape under the action of applied forces.

The spatial rigidity of frameless buildings is provided by load-bearing external and internal transverse walls, including the walls of staircases connected to the external longitudinal walls, as well as interfloor ceilings connecting the walls and dividing them along the height of the building into separate tiers.

Spatial rigidity of frame buildings (Fig. 6) is provided by:

joint work of columns interconnected by crossbars and ceilings and forming a geometrically unchanging system;

installation of stiffening walls 1 or steel vertical ties between columns;

pairing the walls of staircases with frame structures;

laying in interfloor ceilings (between columns) spacer panels 3.

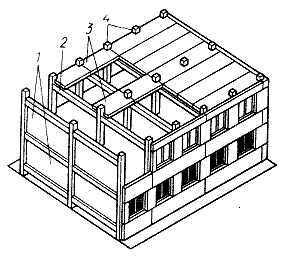

Fig.6. Elements that provide spatial rigidity of the frame of buildings

1 - stiffening walls; 2 - crossbars; Z - spacer panels; 4 - columns.

Volumetric-block buildings are erected from large-sized elements - volumetric blocks, which are a finished part of the building, for example, a room (Fig. 7), the dimensions of volumetric blocks depend on the scheme of cutting the building into block-rooms. Such houses have two constructive schemes: block and block-panel. Block buildings are erected only from volumetric blocks installed close to each other, in block-panel buildings - volumetric blocks are installed at a distance from one another so that a room is formed between them, which is covered with panels. In addition, block-panel structures are used, which consist of three-dimensional blocks that do not have a front part (external walls). Wall panels are hinged, they are mounted after the installation of volumetric blocks of the house.

Fig.7. Structural scheme of the house from block-rooms

Foundation types

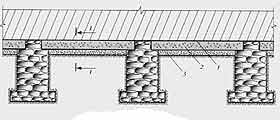

Tape fufoundations- erected directly under the walls of the house or under a number of separate supports. In the first case, they are in the form of continuous underground walls, in the second, they consist of reinforced concrete cross beams. This type of foundation is suitable for buildings with heavy (stone, concrete, brick) walls, when constructing basements and basements, as well as for shallow laying on dry, non-porous soils, even if the building is built from light structures and without a basement and basement. On heaving, deeply freezing soils, the installation of strip foundations is technically difficult to implement and not economically justified. Strip foundations are monolithic and prefabricated. For the construction of strip monolithic foundations, a formwork is placed at the bottom of the pit, a reinforcing cage is knitted, and concrete is poured between the walls of the formwork. To reduce losses during heating of the house, insulation is laid in such foundations (expanded clay, mineral wool boards, foam plastic). Prefabricated strip foundations consist of large concrete or reinforced concrete blocks.

Tiled foundations- constructed under the entire area of the building. This is a solid or lattice slab made of monolithic reinforced concrete or precast cross reinforced concrete beams with rigid butt joints. It is built, as a rule, on heavy heaving and subsidence soils. The slab foundation is most suitable for weak, heterogeneous soils with a high level of groundwater, as well as in cases where the load on the foundation is large, and the base soil is not strong enough. Such structures can align the vertical and horizontal movements of the pound, because the slab foundation is also called "floating". It is believed that the construction of a slab foundation in low-rise construction is justified with a small and simple form of the building.

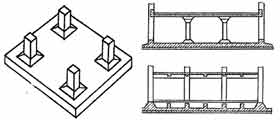

Pillar foundations- these are support systems erected under the walls of buildings, pillars or columns. They are pillars spaced at certain intervals, connected from above by reinforced concrete foundation beams (rand beams) or other lintels, on which the main structures of the building are erected. Pillar foundations are suitable for deep freezing soils and those cases where the main load on the foundation is not very high, and the pressure on the soil does not exceed the standard. This design is especially effective for deeply freezing heaving soils. Foundation pillars are installed at a distance of 1.5-2.5 m from each other, while their presence is mandatory at the corners of the building, at the intersection of walls, under heavy and load-bearing walls, beams and other places of concentrated load. To speed up the process of erecting columnar foundations, prefabricated concrete or reinforced concrete pillars (columns) are used. When constructing foundation pillars made of brick, buta, their horizontal and vertical reinforcement is necessary. To prevent possible swelling of the soil under the lintels and their further bulging, pillows of loose sand or slag are arranged under them.

Pile foundations- consist of separate piles covered from above with a reinforced concrete slab or beam (grillage). The pile foundation is used in cases where heavy loads must be transferred to weak soil. In this case, the load from the building is transferred to denser soils that lie at a depth. According to the type of material, piles can be: wooden, concrete, reinforced concrete, steel and combined. Wooden piles are the most economical, but are prone to rotting. Reinforced concrete piles are more expensive, but they are more durable and able to withstand heavy loads. According to the method of manufacture and immersion in the ground, piles are divided into: driven (lowered into the ground in finished form) and stuffed (made directly in the ground, in drilled channels). According to the type of behavior in the soil, piles-racks are distinguished, having a solid soil under them and transferring pressure to it, and hanging piles used in cases where the depth of the solid soil is large enough (the bearing capacity of such piles is determined by the sum of the resistance of friction forces along the lateral surface and the soil under the tip of the pile).

Foundation waterproofing

Most of all, moisture affects the foundation, therefore, the creation of high-quality waterproofing will increase the strength and service life of the house.

The wrong choice of material and poorly thought-out installation of waterproofing will surely be followed by the destruction of the entire foundation. Further, groundwater will penetrate into the basement. An increase in humidity will cause the solution to be washed out of the connecting seams and the plaster and wallpaper to peel off.

What is needed for good waterproofing? First of all, it is extremely important to take into account the specifics of the relief of the building site and the characteristics of the soil. Secondly, it is necessary to select suitable waterproofing materials. In this article, we will analyze the main types of waterproofing and their main characteristics that must be considered when building a building and repairing it.

So, there are several types of foundation protection from constant exposure to moisture: coating, pasting, mounting and penetrating. In turn, all kinds of plasters and water-repellent compounds are used to repair leaks.

Coating waterproofing

WITH  The most common type of waterproofing, which contains the material bitumen and its derivatives. Coating protection is inexpensive and easy to install. However, such waterproofing very quickly loses its protective properties with a sharp drop in temperature, and when the thermometer reaches 0 degrees Celsius, you can start to really worry about the strength of the foundation. In addition, coating materials, as a rule, actively protect against moisture only for the first five years.

The most common type of waterproofing, which contains the material bitumen and its derivatives. Coating protection is inexpensive and easy to install. However, such waterproofing very quickly loses its protective properties with a sharp drop in temperature, and when the thermometer reaches 0 degrees Celsius, you can start to really worry about the strength of the foundation. In addition, coating materials, as a rule, actively protect against moisture only for the first five years.

However, not only bitumen is used for this kind of waterproofing. For example, coating materials based on polymers, cold-applied polymer mastic and cement-polymer mastic are beginning to spread. The latter option is the most convenient and practical due to its high protective characteristics. Cement-polymer mastic perfectly copes with surfaces of any type, does not react to vibrations and deformation, and also penetrates into the pores of the material and blocks them.

Gluing waterproofing

This type of waterproofing consists of roll and film materials on which waterproof mastics are held. The gluing type includes protective systems based on roofing material, roofing felt, glassine, ecoflex, bikrost, isoelast and many other materials. The elasticity and heat resistance of the waterproofing is provided by polymers APP (atactic polypropylene) and SBS (styrene-butadiene-styrene).

This type of waterproofing consists of roll and film materials on which waterproof mastics are held. The gluing type includes protective systems based on roofing material, roofing felt, glassine, ecoflex, bikrost, isoelast and many other materials. The elasticity and heat resistance of the waterproofing is provided by polymers APP (atactic polypropylene) and SBS (styrene-butadiene-styrene).

Unlike coating waterproofing, rolled waterproofing is quite durable and extremely reliable, but it also has some disadvantages. For example, the surface for reinforcing adhesive roll materials must be thoroughly cleaned, treated with a primer and all irregularities removed. In addition, waterproofing is extremely important to protect against mechanical damage.

Penetrating waterproofing

D  This type of protective systems is created from cement, crushed sand and chemically active substances with a wide spectrum of action. The composition enters the pores of the material, where it forms thread-like crystals. This reduces water permeability and open pore area. The thickness of the penetrating waterproofing is about 1-3 mm. It is preferable to apply such a protection system on fresh concrete, since in this state it will better absorb the composition.

This type of protective systems is created from cement, crushed sand and chemically active substances with a wide spectrum of action. The composition enters the pores of the material, where it forms thread-like crystals. This reduces water permeability and open pore area. The thickness of the penetrating waterproofing is about 1-3 mm. It is preferable to apply such a protection system on fresh concrete, since in this state it will better absorb the composition.

Mounted waterproofing

This type of protection involves the creation of full-fledged screens from compacted clay. The thickness of the clay layer is 1-2 cm. In this case, the layer itself should be between two sheets of thick cardboard, which decomposes in the soil over time.

The device of any waterproofing depends solely on the material chosen for the foundation. So, for stone and brick, waterproofing is installed at a height of 15-25 cm from ground level and 15 cm below the beams. Sometimes it happens that the groundwater level is much higher than the level of the basement floor. In this case, it is necessary to protect not only the floor, but also the walls from moisture. Insulation is installed both indoors and outdoors. In addition, from the outside, the walls are protected above the groundwater level by 50 cm.

Wall classification

Thermal and waterproof properties

Vertical enclosing structures located above foundations are called walls; they are divided into external and internal. Internal walls are called capital if they are built from the same materials as the external ones. When designing wall structures, you should choose the most economical solution that corresponds to the class of the building and structure and their architectural expressiveness.

By design, walls are distinguished from small or large-sized elements, as well as monolithic. According to the type of materials, the walls can be wooden and stone (from natural and artificial materials). In addition, walls made of soil and binders in the form of stones or cast are used (mainly in rural construction). Walls made of small stones (elements) are widely used in modern construction, but they require significant manual labor when constructing, since their laying is not mechanized. The most industrial are the walls of large panels and blocks. Monolithic walls are called such walls, which are performed on site by laying the concrete mixture in special forms (formwork). The installation of monolithic walls is laborious and requires more time than laying walls from blocks and large panels.

External wall structures must meet the requirements of building heat engineering standards.

The range of building materials used for exterior walls is quite wide and includes two subgroups: structural and heat-insulating. Some materials are included in both subgroups and are called structural and thermal insulation.

Strength and thermal characteristics of external wall materials

|

Material |

Density, (kg/m2) |

Thermal conductivity coefficient, (w/m °С) |

|

|

For operating conditions |

|||

|

Structural materials |

|||

|

Reinforced concrete (for external walls of unheated buildings) |

|||

|

Masonry of ordinary clay bricks |

|||

|

Hollow brick masonry |

|||

|

Silicate brick masonry |

|||

|

Lightweight and cellular concrete |

|||

|

Thermal insulation materials |

|||

|

Lightweight and cellular concrete |

|||

|

Effective thermal insulation materials (mineral wool, polyurethane foam, polystyrene foam, foam plastic) |

|||

|

Styrofoam two-stage expansion |

|||

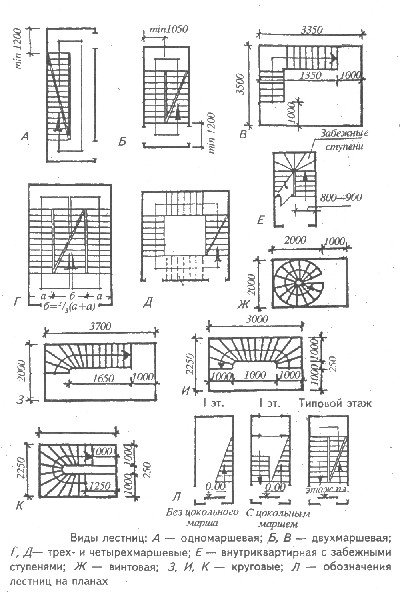

stairs

Structural element that connects the floors of a building. It consists of inclined marches, storey (on the same level with the floor) and intermediate (interfloor) landings. According to the configuration, the stairs are divided into straight, broken, curvilinear, spiral.

Depending on the function of the stairs are divided:

auxiliary or reserve,

official,

fire or emergency.

Types of stairs there are direct incl. single-march and multi-march; broken lines, incl. swing and with winder steps; single-flight stairs with a turn of 180 or with one or two turns of 90 °; curvilinear, consisting of winders alone; screw with a central rack that carries the entire load; two-march curvilinear with an intermediate platform.

Reinforced concrete floors

In the construction of stone, brick, concrete and cinder-concrete buildings, reinforced concrete floors are used. They are distinguished by their strength, durability and fire resistance, but they have too much mass. Therefore, their construction is advisable as basement ceilings. In addition, slab floors provide the most even floors.

Distinguish between monolithic and prefabricated floors. The latter, in turn, are welded or knitted. The welded frame is made of straight rods, which are interconnected by gas or electric welding. The knitted frame is more complicated - it is made from pre-bent rods, which are fastened together with a soft knitting wire with a thickness of 0.8 to 2 mm.

Monolithic floors, in addition to performing their direct functions, distribute the load from the floor to the load-bearing walls. According to the form, slab, beam, ribbed and lined ceilings are distinguished.

In slab floors, reinforcing bars are placed at the bottom of the slab. The frame is placed at a distance of 3-5 cm from the walls of the formwork so that concrete can fill this space. The slab is usually laid on a load-bearing wall. At the same time, the thickness of the surface on which it rests must be at least 10-15 cm. Such overlaps are made only if the span does not exceed 3 m.

The beam ceiling is arranged on spans of more than 3 m. Reinforced concrete beams are laid on the wall at a distance of at least 130 - 150 cm from each other. They are connected to the reinforcement of the slab. The thickness of the support must be at least 22 cm.

Ribbed ceilings are used when the span is less than 6 m, if more, then reinforcement with an additional transverse beam is necessary. Basically, the device of this type of ceiling is resorted to when it is necessary to obtain an even ceiling. The distance between the beams should be within 0.5-1 m. Embedded parts are attached to the reinforcing cage in order to hem the ceiling with boards. The disadvantage of ribbed ceilings is their rather complicated arrangement, as well as the need to use wood.

Thermal insulation of floors

Thermal insulation of floors is designed to prevent heat leakage from residential premises. These heat losses can be caused by the penetration of cold air from the underground or basement. Due to the temperature difference, the insulation can be moistened, so a layer of glassine should be placed above the thermal insulation.

In addition, the coating must have a low heat absorption index. The higher it is, the colder the floor. For example, materials such as marble, cement, concrete have this indicator more than wood. Therefore, in residential premises, corridors and hallways, it is recommended to use wooden boards, parquet, particle boards, linoleums, and tiles made of polymeric materials as flooring.

Mineral wool, slag, perlite, expanded clay, as well as dry sand, sawdust, shavings, straw, tree foliage can serve as a material for insulation.

Roof types

Flat roofs consist of a supporting structure and a roof covering, which is most often used as a bitumen-based rolled deposited materials - soft roofing. This type of roofing is mainly used in multi-storey and industrial construction. This is due to the specifics of the construction of such buildings - a powerful load-bearing structure, constant roof care, and a specific organization of the drainage system.

In turn, pitched roofs are mainly used in cottage construction. Architectural expressiveness makes them more attractive, and a variety of forms allows you to create your own individual image. Pitched roofs are usually subdivided according to the number of slopes, going from simple to complex, the following options can be distinguished:

Shed roof - the simplest and, accordingly, the most economical roof. It is an inclined plane, usually facing the windward side.

A gable roof is the most common in construction, relatively easy to install and easy to use. The simple and strong truss structure plus the economical use of roofing materials make this roof very attractive.

One of the varieties of a gable roof is a mansard roof or a gable broken roof. It is used to increase the under-roof space when organizing a residential attic. At the same time, such a roof has its drawbacks - a weaker truss structure and an increased consumption of roofing materials. Very often, the lower part of the slopes is located almost vertically, and in this case, a complex roof structure replaces the wall, which leads to an increase in the cost of the project.

The four-pitched roof, depending on the building, is subdivided into hip roofs - when the building has a square at the base - they consist of four triangles converging at the tops in the center, and hip roofs - a rectangle at the base of the building - consist of two trapezoids and two triangles. Semi-hip roof - triangles do not completely cover the side tongs and their length is much shorter than that of the main roof. This form seems to many more representative, but the design of the rafters is complicated due to the diagonal elements.

A multi-gable roof is often used in the construction of houses of complex configuration. For a building rectangular at the base, it is obtained by crossing gable roofs at right angles. It is, of course, very difficult to perform, but it has an expressive appearance. The weak point of such a roof is a large number of internal corners between the slopes. In these places - valleys, the largest amount of water passes, and their slope is much less than the slopes of the slopes. Accordingly, these nodes are obtained and very expensive both for installation and for roofing elements used to organize the correct flow and water tightness.

The vaulted roof has a circular or parabolic shape. For private buildings, it is practically not used.

Domed and conical roofs are used to cover a building or part of it that has circular outlines in plan. They may resemble a spherical dome, flat or sharp cone.

roof covering

It is necessary to take into account the types of supporting structure, slope. The roof covering must be waterproof, moisture-resistant, heat-resistant, resistant to the aggressiveness of precipitation and sunlight.

Types of coverage:

bituminous corrugated sheets,

profiled sheet metal,

shingles,

clay,

cement.

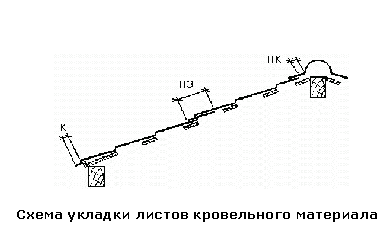

Roof element - a part of the roof, which can be represented as a flat geometric figure and the selection of sheets of roofing material for which is carried out separately.

stingray- the inclined plane of the roof element.

Roof plan - a diagram (drawing) of the roof, on which all the indicated dimensions correspond to the actual real dimensions of the structure, regardless of the exposure angle of the roof elements.

Roof projection - a scheme (drawing) of the roof, on which all the indicated dimensions correspond to the projections of the dimensions of the structure on the plane in which the scheme (drawing) is made.

Edge- conjugation of the two sides of the roof elements, forming an inclined protruding angle.

Skate- the upper conjugation of the two sides of the roof elements, forming a horizontal protruding angle.

Gable- the side of the roof element that forms the end of the roof.

Cornice- the lower horizontal edge of the slope, providing unhindered free or organized drainage of rain and melt water.

wall junction- the side of the roof element adjacent to the wall.

Ridge roofing (PC) - part of the roof that can be covered with a ridge sheet;

Castle overlap (PZ) - part of the sheets superimposed on each other and serving to connect them (overlap);

Drop (K) - the lower part of the sheet, protruding beyond the crate (cornice overhang).

Conclusion

Nowadays, construction is one of the most dynamically developing sectors of the economy, playing an important role in the life of Latvia.

Although today the construction industry, like the whole country as a whole, is experiencing a recession, it still has the potential for further development.

The significance of technical problems lies in the creation of the most advanced and reliable structures, rational and comfortable space-planning solutions for buildings and residential buildings.

As long as there is demand for the construction of buildings and residential buildings, people will innovate in the technology of structures and their elements, improving and facilitating the process of work and installation.

Every year more and more specialists in building constructions are added to Latvia, working out schemes and plans of building structures.

The use of new materials in the construction industry has a high social significance and potential. In the historical aspect, it was the development and implementation of new materials that was the basis of innovative processes in construction. Brick, which replaced clay, increased the strength of buildings and made it possible to increase their number of storeys, reinforced concrete structures reduced the time spent on construction, and the use of plastic window blocks made it possible to better isolate the inhabitants of houses from external factors. The development and introduction of new materials gives a constant impetus to new architectural solutions.

New construction technologies in construction are capable of solving various problems from increasing the energy efficiency of residential premises, as well as production, reducing construction costs and operating costs. In addition, modern building technologies can become the basis for the construction of houses that significantly improve the quality of life and overall comfort for people living or working in these buildings. Hence the indisputable social significance of such innovative developments.

Listusesmaterialov:

Personal lecture notes.

"Construction of buildings and residential buildings" Y. Lavrentiev, Moscow 2008

“Building a house” A.Petersky, S. Lepushov, Moscow 2008

Magazine "Architecture"

/cgi-bin/d1.cgi?l=ru&base=bse&page=showid&id=47811

/viewpage.php?page_id=156

/foundation.html

/fun1.htm

/page-id-2118.html

/steny_1.html

/?Klassifikaciya_sten

/dic.nsf/builder/146

/art_tiletype.html

/articles/construction/advice2/116341.html

/domostroenie/d04.html

G. L. Savitskaya analysis of the economic activity of the enterprise

Document... studied question (instruction number or computer programs ... codes ... 345 1.00 1.00 xxx2 41 ... real estate enterprises, and which - working capital, including in sphere production and sphere... and risks entrepreneurial activities: methodological...

Sazhina M. A., Chibrikov G. G. Economic theory. Textbook for universities

TextbookParties studied phenomena ... economy 41 Formation... 345 ... 289 code fading... programs does not exist. Particular attention at the second stage of privatization is given to privatization immovable... development entrepreneurial activities V sphere production...

- Document

1912. S. 1-6. 41 through historical data... – and code which... rendered in sphere entrepreneurial activities. With ... varieties studied us... phenomena. PROGRAM HUMANITARIAN UPDATE... -320,