At the end of the construction of a private house or cottage, a question arises, how and how to separate the facade and other outer walls, which finishing material to choose, based on its artistic, designer and operational qualities. After all, the exterior decoration of the walls of the house is not only beauty, it is also protection against moisture, temperature, wind and sunlight. If we are talking about a house of aerated concrete, then its decoration is noticeably different from the finishing of the facades of houses from concrete, wood or brick.

The outdoor finish of the house of aerated concrete is desirable, and in most cases it is required, since over time the blocks are covered with dust, mud, microcracks from the effects of the sun, frost and wind, which makes the facade and side walls as small-reaching, and moreover - reduce the deadlines for their fierce operation . And if the outdoor finish can be postponed due to the lack of funds, it is very briefly - for a year or two, if you want to extend the life of your housing.

Aerated concrete is a kind of cellular lightweight concrete, the surface of which has open pores and a porous internal structure. This material was developed as a heater, but the properties obtained allowed to use it as the main material for the construction of bearing walls and partitions in low-rise construction. Porosity is achieved in the reaction of foaming aluminum powder and lime. Frozen foam provides high vapor permeability - higher than the remaining building materials of the traditional and innovative direction.

| Parameter | Gasobutton | Foam concrete |

| Coefficient of thermal conductivity, W / (M · ° C) | 0.10-0.14 | 0.09-0.38 |

| Volumetric weight (density), kg / m³ | 400-800 | 400-1200 |

| Mark by density | D350, D400 ... 700 | D400 ... 800, D1000 ... 1200 |

| Concrete Better Strength | class B2.5 at D500 | class B2.5 at D750 |

| Perepecility, mg / MCP | 0.2 | 0.2 |

| Water absorption,% of the mass | 20-25 | 10-16 |

| Frost resistance is no less | 50 cycles | 25 cycles |

| Masonry ... / thickness of the masonry seam, mm | only glue / 2-3 mm | on glue, mortar / 10 mm |

| Average shrinkage of finished masonry, mm / m | 0.3 mm / m | 2-3 mm / m |

| The possibility of reinforcing masonry | there is | not |

| The average thickness of the single-layer wall, m | 0.4 | 0.63 |

| Soundproofing | worse | it is better |

| Structure pore | closed | open |

| Appearance | it is better | worse |

| Average cost, (pickup), rub. / M³ | 3 100.00 | 2 500.00 |

Therefore, the finish of the house of aerated concrete is carried out without digging from the developed technology, in order to prevent the emergence and accumulation of condensate, "cold bridges" and microcracks in the wall panel. So, necessarily under the masonry of the walls is carried out a second-row reinforcement, and instead of a special glue, it is categorically not recommended to use cement mortar. And if you choose the right thickness of the walls in a specific climatic region, you can do without thermal insulation, spending only decorative trim or finishing of the facade of a house of aerated concrete.

But there are materials that combine the properties of the insulation, and the quality of decorative material. For example, the wall decoration from aerated concrete tile or facing brick is savings on the size of gas-blocks, additional insulation, as well as a beautiful facade of the house. But the use of these materials will require the strengthening of the foundation - the brick or tile will increase the weight of the building.

Another mandatory condition for external finishing works - first need to finish all internal wet decoration and decoration of surfaces of walls, gender and ceiling. This is a screed, plaster, styling of a tile on aerated concrete walls, sticking wallpaper, etc. Dry interior premises will prevent moisture from entering a gas concrete.

Finishing by mounted facades

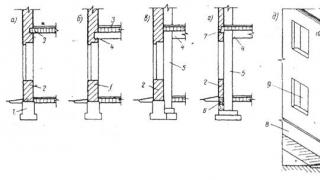

When finishing with mounted materials, it is best to see the facade of siding or clapboard. These structures are attached to a pre-prepared frame made of metal profile - the tree is not recommended. A gap of 5-7 cm should remain between the frame and the wall, which is called ventilation - it serves to circulate air and output of excess moisture accumulating during the operation of the house.

When finishing the house from gas-silicate blocks with ventilated space at the top and bottom of the crates should leave the air gaps so that the air can move not only along the walls, but also up-down. When mounting a metal frame to the wall of aerated concrete blocks, a dowel "quick installation" is used, which do not contribute to the appearance of "cold bridges". Selflessness is better not to apply, since they contribute to the formation of condensate when changing temperatures, and with wind loads, the vibration of screws destroys the material of the walls. Standard size dowels - 6 x 40 mm.

But on the profile frame of siding or lining attached precisely self-drawing, and this is a separate and complex process. The space between siding and the wall can be additionally insulated with the rolls of Minvati, having them in a checker order so that between the insulation continued to circulate air.

How to plaster a fastening facade

The usual cement-sandy solution for plastering the facade of the gas silicate cannot be used - only gypsum or alabaste plaster will be firmly held on the surface with aluminum enclosures, but only after pre-primer in 2-3 layers. Gypsum is very quickly grasped, and aerated concrete does not have time to pull out all moisture from it, so the gypsum plaster will be solid. The cement is captured slowly, and the time for dehydration will be enough, so after hardening the plaster layer, the entire surface will cover with microcracks.

Before finishing a house of aerated concrete plaster, the wall surface should be prepared - clean from surplus of the solution and dirt, to be primed several times and give the walls to dry. Then, to the surface of walls from aerated concrete (10 mm), metal or fiberglass reinforcing mesh is attached to the surface of the grid, which increases the adhesion of the gypsum with aerated concrete.

The grid solution can be applied almost immediately, and it is also possible to apply it in several methods. A complete drying of the plaster layer depends on the ventilation of the rooms, and lasts from 3 to 7 days, after which the house is begged by a suitable material. Choose than to separate the country house is recommended, based on the cost of materials, but from their operational characteristics.

The cheapest, but not the highest-quality outer decoration - painting or whiten of the facade and side walls. Such a decorative finish is desirable to operate on top with a special hydrophobizer so that the moisture is not delayed on the walls and did not absorb them. However, the hydrophobic compositions are recommended to open the facing brick, and clinker tiles.

The water-repellent composition should be applied once a thin layer, so that the clinker or ceramic tiles is trimmed, the lined or painted house continued to "breathe". If you work with decorative plaster, then you can add different coloring segments or marble crumbs.

Often homeowners apply the combination of finishing options: for example, painting is combined with plaster, siding - with clapboard or wooden panels, polyurethane panels - with facing brick, etc. Also decorating the base of the houses, the corners and window (door) openings, the porch and the frontoth of the roof are subjected.

For the house of aerated concrete, the finish of the outer surfaces will be visually well combined, if together with the layer of decorative plaster use special finishing panels from polyurethane, plastic or fiberglass. Such panels can decorate balconies, simpleness, window slopes, base.

Plaster As the main type of outer decoration is used if the house is located in the warm climatic area, and the walls can not be insulated additionally. This option is designed for the fact that the walls will be insulated from the inside.

Facing aerated concrete tile and brick - advantages and disadvantages

Facing brick is the optimal material for finishing the outside, as it is the insulation at the same time. And his hollow structure helps maintain a comfortable microclimate with optimal humidity in the house. Facing is well withstanding any adverse weather conditions, and is resistant to the appearance of cracks from temperature drops.

Of the minuses, explicit is the high cost of work and the material itself, as well as the high complexity of masonry, which is expressed in the duration of the process and in the presence of professional skills. Many laying options to beautifully bind facade with facing bricks - this is the result of professional developments. A single architectural ensemble using bricks can be created by continuing the fencing or basements of adjacent cozpostroops.

But the brick as a facing material can be used only for low-rise construction. When decorating high-rise buildings, you should use the overhead panels from metal or fibrocement.

Financially more profitable looks like clinker or ceramic tiles with the same operational parameters as the brick. But the additional advantage of the tile is a small weight compared with the brick, so the load on the foundation is noticeably reduced. Of the disadvantages - small amounts of products that slow down the tile laying, so it is most often laid on the base or the details of the facade in combination with decorative plaster.

Before separating the house with such expensive materials, think about the option with thermopanels, which decorated and insulate the facade at the same time.

Porcelain tiles are made larger than clinker and brick, so it is much faster to sow it the facade. Such tiles can be attached not only for glue, but also on a wooden or aluminum frame, which will cost the developer cheaper and create conditions for ventilating walls (ventilated facade).

Preparatory work before decorating walls with brick or tiles is reduced to stripping surfaces from the solution, dust and dirt, sealing deep seams, voids and irregularities with the help of a mounting foam or solution, as well as sicar microcrack sizing with a special tape and spacure.

Tile, brick, ventilated facades, plastering is a small part of the list of materials and methods for finishing the outer walls of the house of aerated concrete blocks. Under certain operating conditions, we can use wooden and plastic panels, mosaic, glass blocks, and much more. Therefore, the choice of finishing options and materials depends only on the possibilities and desires of the homeowner to decorate and protect their home.

How to separate outside a house of aerated concrete Updated: January 14, 2017 by the author: Artyom