The walls are erected in accordance with the project of the house, in which all data necessary for the construction of the walls should be indicated. It is also important that specialists with experiences who know the sequence of actions and have the appropriate specialty (bricklayers, carpenters, etc.). If the wet processes are used, the walls of the house must be built into the warm, dry season, the temperature is not lower than +5 degrees C.

The choice of material for the construction of the walls is made on the basis of strength calculations, heat loss, the features of the design of the wall itself and the combination of material with the foundation and roof is taken into account. Adopted design solutions on type, brand, thickness, etc. change is not allowed. Thickness (length) of wall blocks, or the number of bricks in the masonry, or the diameter of the logs, the cross section of the bar, etc. must accurately embody on the construction site in accordance with the design solutions. Various and even very unusual walls, such as glass and metal, can be designed. But further consider the features of the structures and the features of the construction of the most common options.

Popular design options

- A single-layer wall may consist only of porous ceramics, foam concrete, thick wood, i.e. Low thermal conductivity materials. But at the same time, a single-layer wall of well-known materials may correspond to heat-saving regulations only in the southern regions. And in the northern heat-saving properties of the single-layer wall will be clearly insufficient, or will have to significantly increase the thickness of the layer.

- The two-layer is laid out of any building material, which is formed by the carrier layer and is covered with heat insulator. It is a universal option and can be used in any climate, as the heat-saving properties will be determined by the solar thickness.

- In the three-layer design, the heavy facade layer is also laid out, which can significantly affect the strength, heat-saving, vapor permeable wall quality. As a rule, it is a high-quality durable decoration of solid piece materials.

The importance of quality work

![]() When choosing any material for walls or any wall design, first of all, it is necessary to pay attention to the selection of specialists who will erect this wall. The experience is taken into account first of all, the experience of accomplishing similar works. The wall of the house consists of a variety of fragments, each of which must be individually laid correctly. And it will depend on the builder. Therefore, preliminary conversations with employed experts, checking their certificates and documentation, inspection of the facilities erected earlier and collect feedback on their work - the usual concern for a private thoring man, who wants the walls of his houses to be built as follows.

When choosing any material for walls or any wall design, first of all, it is necessary to pay attention to the selection of specialists who will erect this wall. The experience is taken into account first of all, the experience of accomplishing similar works. The wall of the house consists of a variety of fragments, each of which must be individually laid correctly. And it will depend on the builder. Therefore, preliminary conversations with employed experts, checking their certificates and documentation, inspection of the facilities erected earlier and collect feedback on their work - the usual concern for a private thoring man, who wants the walls of his houses to be built as follows.

Consider the features of the construction of walls from the popular building materials today.

Walls from aerated concrete

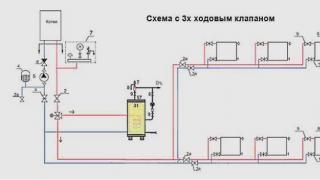

The low price of aerated concrete, simplicity and speed of construction - the main trumps of this material. A counterweight is low reliability, fragility, water destruction. The main point during the construction is not allowed wide seams. Maximum seam thickness - 3 mm. The statement is carried out only on a special glue. This is insured from uneven stresses on the wall, as well as from unnecessary heat loss. The foundation for aerated concrete is created only a ribbon monolithic non-admissible movement, the design of which is provided for by the project. Because foam concrete has low elasticity, fragile.

The enemy of foam concrete is water. If through the finish, or from the roof, or due to the violation of steam exchange in the wall, or due to the capillary water supply of water from the foundation, the blocks are wedged, they will mock, they will very quickly come into disrepair, collapse. The house will cease to exist as such. Therefore, the issue of waterproofing, and a normal steam exchange in project documentation and special attention is paid to the construction. It is unacceptable from the outside to apply vapor barrier finishing layers, but at the same time, the finishing with such quality should be from the inside. Also, the finish must be low air permeability, since the masonry \\ "breathing \\".

For erection in one layer, structural-heat insulating foam concrete brands D500 - D800 is used. The heat transfer resistance of 400 mm thick with such a material will be only about 2.2 m2 to / W, which is less than the regulatory value for a temperate climate by 30 - 40%. Therefore, in principle, single-layer walls will be considered cold.

For two and three layer structures, it makes sense to apply a colder structural foam concrete more than D600, with an additional layer of thermal insulation.

Monolithic walls

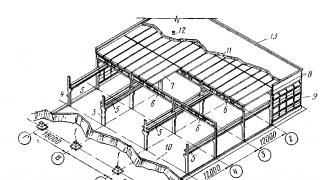

Walls poured from heavy concrete are increasingly gaining popularity. A non-removable formwork technology is applied when the wall is assembled from the hollow blocks made of polystyrene foam from the outside, and from the inside - smooth plaster finish. Blocks are installed on the foundation, and concrete is poured into the cavity. As a result, it turns out immediately finished two-layer wall with outer insulation, and the facade is placed on the fiberglass grid.

The economic feasibility of the walls of the walls in a non-removable formwork or in the moving formwork occurs when performing a large amount of construction work, for example, when erecting a cottage village, when the construction site is mounted for the manufacture and delivery of finished concrete pumps to the fill point.

Usually the fill is performed by specialized construction organizations according to the approved technology. However, manufacturing on the site of lightweight concrete - slag concrete, ceramzite concrete and pouring it into the formwork can be performed manually.

From heavy piece materials

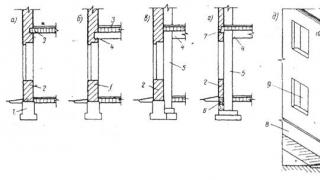

Brick, heavy slag block - ordinary materials for the construction of walls of private houses. Laying is performed manually and depends on the work of a specialist. It is important to withstand one thickness of the seams and their location in one line. The verticality of the walls is controlled, the flatness of the plane of their surface.

The seams between bricks may not be filled with a solution to a depth of up to 1.5 cm, such a laying is called the inlet and is intended for later plastering so that the plastering layer is better to hold onto the wall. If it is not planned to plaster, then the seams give some curly shape - convex, concave, such a masonry is called under the extension.

Also, heavy block materials are also used - various w / w designs, processed and not processed stone, etc.

The side of the piece material is the largest in the area - the bed, the smallest - the stump, the middle - spoons. A number of material laid along the edge of the wall (on the edge) is called the vest. Inner row - shelter. Depending on which side of the material is visible in a row of masonry on the facade (on the verst), the row is called tychkov or spoonful.

Brick walls are not cheap. But they are the most reliable and practical. Their construction can be fulfilled even by one private specialist.

From wood

Wooden houses from glued timber, as well as brick, not cheap, but this building material is worth it. The glued timber during the manufacture is impregnated with "chemistry", does not rot, does not crack, loses fire hazard. It is made of dried up to 7 - 9% of the lamellae, it does not lead it and it does not give a shrinkage. Brous width can reach 40 cm that in a non-cold climate almost enough to regulatory values \u200b\u200bfor heat transfer resistance. The usual 20 cm walls of wood need insulation, i.e. Must be two-layer. Cheap option - the construction of wooden walls from a rounded log. But you need to be prepared that throughout the time up to 5 years old house will give a shrinkage, cracks will appear that need to be caught and others. Possible rot.

Wooden houses from glued timber, as well as brick, not cheap, but this building material is worth it. The glued timber during the manufacture is impregnated with "chemistry", does not rot, does not crack, loses fire hazard. It is made of dried up to 7 - 9% of the lamellae, it does not lead it and it does not give a shrinkage. Brous width can reach 40 cm that in a non-cold climate almost enough to regulatory values \u200b\u200bfor heat transfer resistance. The usual 20 cm walls of wood need insulation, i.e. Must be two-layer. Cheap option - the construction of wooden walls from a rounded log. But you need to be prepared that throughout the time up to 5 years old house will give a shrinkage, cracks will appear that need to be caught and others. Possible rot.

The wooden house is built quickly, for its construction it is necessary to conclude a contract with masters specializing in working with a tree. Since in each case there are many big and small nuances.

The construction of walls in any case requires the presence of a specialist in the construction site. It is possible to save on qualified workers, and the "beginners" can be performed all the hard work, but one specialist must necessarily monitor the entire process and should be responsible for the end result of the walls.