Let's talk about the organization of a hot water supply system with recirculation. Thanks to this water supply scheme, hot water circulation is constantly maintained in the DHW circuit.

Benefits of DHW circulation and scope

Situations are quite widespread when in private houses the entire water treatment system is combined in one technical room, as far as possible from the habitable zone. You can also often find projects of houses with several bathrooms, including on different floors. Such situations are characterized by a significant length of hot water pipelines, which promises residents some inconvenience.

For example, when opening a hot spot of water intake, it takes time, sometimes quite a lot, until the water, having passed through the channels and giving them part of its own heat, begins to flow from the tap at a nominal temperature. This not only causes certain inconveniences with each use of the bathroom, but also leads to excessive consumption of water, which in many private construction projects serves as a strategic resource.

The problem is solved by a recirculation unit that maintains a constant flow in the DHW system. Thanks to this, hot water flows from the tap immediately after opening, in addition, its temperature can be precisely adjusted regardless of the operating mode of the heating device.

Recirculation units can be equipped with those systems in which the storage heater, indirect heating boiler or the second circuit of the boiler is responsible for heating the water. When using flow-through gas and electric heaters, it is much more reasonable to move them closer to the draw-off points.

It should be noted that DHW recycling implies a completely different system topology. Therefore, the implementation of such an idea is possible only in the process of construction, or at least a major overhaul. When trying to refine the existing plumbing complex in order to organize recycling, it is unlikely that it will be possible to get by with little bloodshed.

Pump assembly and piping

The layout of the recirculation unit may differ depending on the water heating and pumping equipment used. For example, the design of some indirect heating boilers provides for a third outlet from the upper third of the tank to connect the return recirculation pipe. If there is no such outlet, the return flow is connected through a tee to the cold water supply pipe.

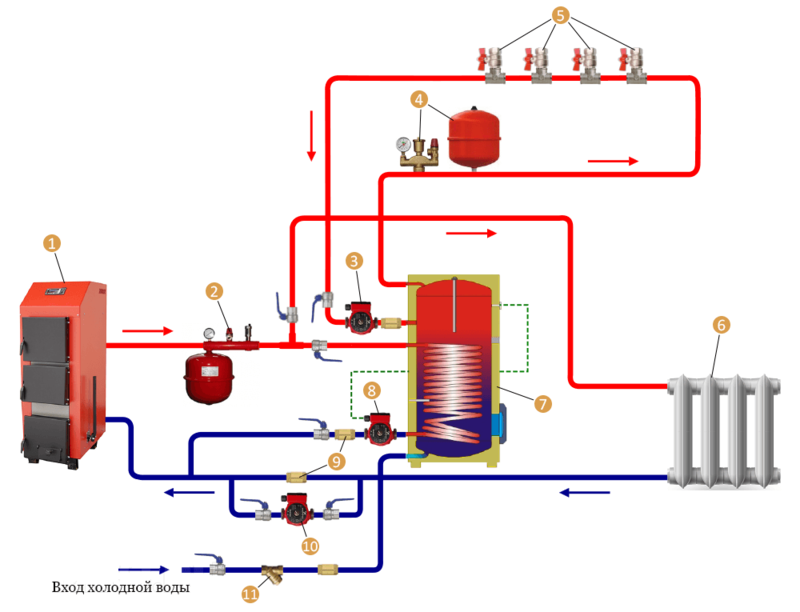

An example of a piping scheme for an indirect heating boiler with DHW recirculation: 1 - heating boiler; 2 - boiler safety group with expansion tank; 3 - circulation pump of the DHW system; 4 - boiler safety group with expansion tank; 5 - consumers of hot water; 6 - heating radiators; 7 - indirect heating boiler; 8 - boiler circulation pump; 9 - check valves; 10 - circulation pump of the heating system; 11 - coarse mesh filter

If we take as an example a standard electric water heater with two outlets, then a detachable connection with a union nut and a safety group for boilers are first installed on the cold water supply pipe. A tee is mounted below, on the two free branches of which ball valves are installed. One of them is intended for connection to the cold water main, the other for the return pipe of the recirculation loop.

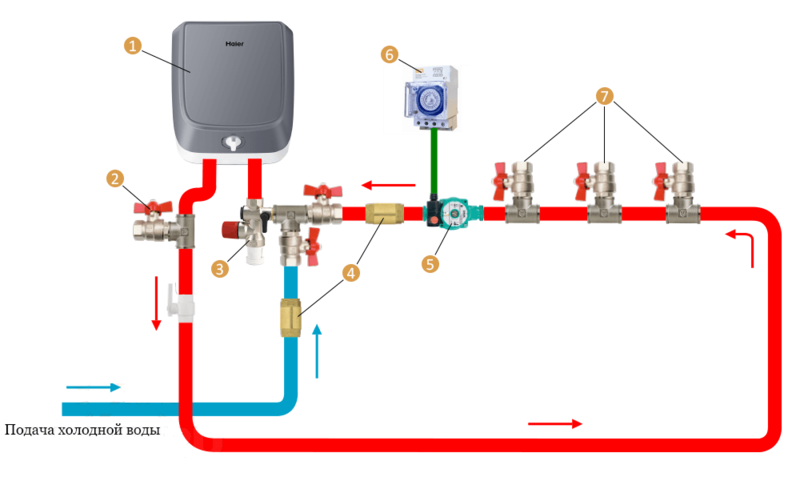

DHW recirculation scheme with storage boiler: 1 - storage water heater; 2 - tap for air suction when draining the tank; 3 - security group; 4 - check valves; 5 - circulation pump; 6 - weekly-daily timer; 7 - hot water consumers

Thus, the supply of cold water to the system occurs only when the pressure drops from the opening of the water intake, in other cases, hot water circulates through a closed loop that includes the entire volume of the boiler.

This is the main disadvantage of water heaters, the design of which does not provide for their use in DHW systems with recirculation. With such a connection scheme, the boiler will not, as expected, give 2/3 of its volume with a consistently high temperature, because when fed, the entire volume of liquid will be evenly cooled.

As for the pump itself, for this purpose, leading manufacturers of sanitary equipment (Wilo, Grundfos) have developed a whole series of devices. Their main difference from standard circulation pumps is the threaded connections for connecting the same standard size that is usually used in domestic water supply systems - for 1/2" or 1/4" threads.

Otherwise, such pumps are almost completely identical to the equipment used in heating systems with forced circulation of the coolant. Of the additional functions, performance adjustment, a daily-weekly timer and a thermostat may be available.

Piping system

The best material option for arranging a recirculation system is polyethylene pipes (PEX) with sliding press fittings. Yes, the installation of such systems requires the use of special expensive equipment, but it is quite possible to get by with a set of hand tools for crimping, rented. At the same time, in terms of moldings, the pipes themselves are much cheaper than polypropylene and metal-plastic ones, and their service life is incomparably higher.

In any case, the pipeline layout is quite simple. Its first part, which supplies water to sanitary equipment, is mounted in a continuous line from the heating unit in series to each draw-off point. At the last point in the chain, the pipeline does not end, it returns back to the heating unit. This circumstance must be taken into account when considering various laying schemes in order to minimize the consumption of materials for organizing a loop.

Before laying, each individual segment of the pipeline is dressed in belt thermal insulation made of foamed polyethylene or rubber. The latter material is more preferable for those pipe sections that will subsequently be walled up. Thermal insulation should be placed close to the fittings, all joints between the shell must be glued with metallized tape.

Operation and modes of operation

In the summer, when there is no need for space heating, recirculation can simply be turned off by de-energizing the pump and turning off the tap on the back of the loop. True, for this, the forced circulation device must be placed according to the scheme after all points of water intake.

DHW recycling can be automated relatively easily. Even if the pump is not equipped with a built-in programmable timer, nothing prevents you from installing a separate control device and turning off the system at night or in the absence of the owners. If the housing is equipped with a home automation system, you can set up a recycling system based on Smart Home algorithms or a security alarm.published

If you have any questions on this topic, ask them to specialists and readers of our project.