Today, it is easily organized thanks to heating and water-heating equipment. The units are produced in ergonomic designs with modern control and management systems, so the owners of country houses do not have any particular difficulties with the private use of such equipment. At the same time, a lot depends on the water supply scheme and equipment connection configuration, including energy costs. In this context, the most developed and profitable system is DHW with recirculation of the coolant.

The principle of operation of a conventional DHW structure

The traditional DHW system is carried out according to the scheme of simple wiring of cold water circuits with bottling, abutting against dead-end risers. The elevator unit can provide two tie-ins for filling: on the return and supply lines. According to the heating schedule, the direction of DHW recirculation is changed by switching between the circuits. The active flow is shifted from the return to the supply and vice versa (depending on the season and temperature conditions).

What are the disadvantages of conventional hot water?

The advantages of such schemes include easy maintenance and low implementation costs. But in practice, there are also quite significant drawbacks. So, why do many people use hot water recirculation instead of conventional wiring? The lack of effective and timely water intake leads to cooling of water in underwater channels and risers. This means that every time the hot water is turned on after a certain break, it will require a waiting time of several minutes. At this time, cold water simply drains. As a result, in the long run, the costs of an unused resource accumulate for its intended purpose, not to mention the time spent waiting for hot water treatment.

How is a recirculation system different?

If the usual DHW scheme involves the withdrawal of water with an unsuitable temperature regime into the sewer, then recirculation ensures a constant transition of the liquid through the spills between risers and inlets. In this case, only water used for its intended purpose is drained. Also, the DHW recirculation system has the following advantages:

- Hot water flows without delay at the draw-off point, regardless of the removal of the circuit. The difference in delivery time may depend only on the quality of the pipeline layout and the efficiency of the pump that maintains pressure in the system, but recirculation as such, in principle, allows you to eliminate the slightest hitches in the delivery of the coolant.

- In apartment buildings, heated towel rails are transferred to the riser from the intra-apartment hot water supply. Continuous circulation in such a scheme makes the streams hot all the time. In private houses, the same thing happens, only instead of a riser there is a separate bottling.

- The temperature in the circuits stabilizes. Thermal management depends on the settings in the thermostat (if there is an appropriate control unit), and not on cyclic cooling and heating.

Are there any downsides to recycling? Of course, this system requires the use of additional functional elements, but practice shows that savings in the process of DHW operation justify organizational investments.

Equipment for the recycling system

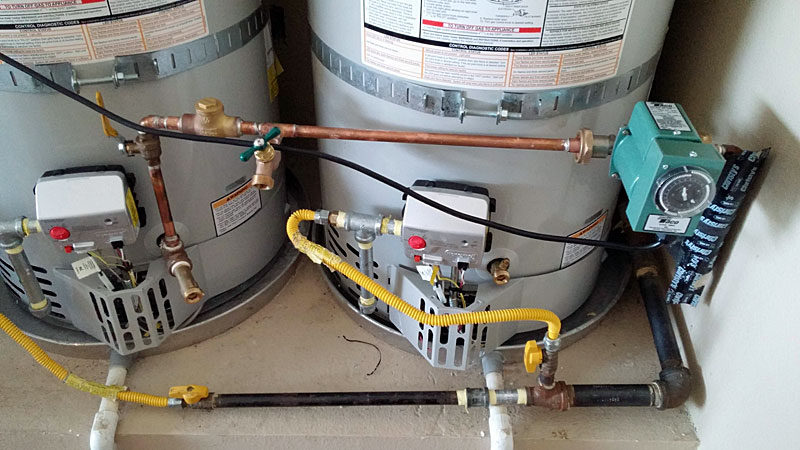

A typical water supply infrastructure with recirculation includes the following components:

- The source of thermal energy is a boiler (mandatory double-circuit). Gas and electric models can be used depending on specific supply options. In the case of the same country house, there is not always a gas main, but it can be replaced with a gas tank or, at worst, cylinders. The disadvantage of electricity lies in the high financial costs, but this solution is safer and more reliable in any case.

- Boiler. A storage unit with a volume of 30-40 liters will be required if we are talking about a family of 3 people living in a private house with several hot water consumption points. Also, a DHW boiler with recirculation must have its own temperature control sensor, which will automate the process of regulating the coolant through a thermostat.

- Circulation pump. Actually, the main component that distinguishes the recirculation system and, in principle, makes it possible to rationally use water supply circuits.

How to choose a DHW recirculation pump?

The choice should be based on the technical and operational characteristics of the device, including power, performance and parameters of the connection pipe. The optimal power potential is 20 watts. Such a model can serve a house with an area of more than 200 m 2, releasing about 30 l / min through the pump. Productivity up to 50 l / min and more is provided by industrial units of 30 W or more, originally designed to work with large volumes of liquids, including technical ones. For domestic use, 15 watts may be enough.

As for equipment manufacturers, Grundfos, AL-KO, Grinda and Elitech products are among the best solutions. For example, the Grundfos ALPHA3 25-40 DHW recirculation pump is considered one of the best in class for houses with an area of 200 m 2. Its stainless steel construction can be used in service environments with temperatures up to 2-110 °C. As for the technical parameters, the size of the nozzle is 25 mm, and the head reaches 40 m, as can be seen from the marking. According to experts, this model reduces fuel costs by up to 20%, and pays for itself in 2 years of use in an average operating mode.

Recycling in apartment buildings

The main task in ensuring recirculation in the circuits of apartment buildings is to form a ring with a continuous movement of the coolant. This is done in the following ways:

- Two bottlings of hot water are initially brought to the building. Connection to the risers is carried out alternately. As an option, it is possible to offer a divided connection of bottling - one only to the risers, and the second - to the heated towel rails.

- The risers are combined (if necessary - with heated towel rails) using jumpers on the upper technical room. Up to 4 risers can be combined in one group. A Mayevsky crane (air vent) is installed in the jumper node, thanks to which excess air will be bled from the circuit.

In order for the described DHW recirculation scheme to work, a pump is needed. It is cut between bottlings and risers (towel dryers). If necessary, several circulation pumps are used. To switch operating modes when changing heating seasons, a manifold with an elevator and tie-ins on the pipe entry flanges is installed.

Implementation of the system in a private house

It is possible to loop the DHW line by transferring a distant bottling to a water supply point. The optimal recirculation scheme assumes the presence of three nozzles - a standard heating system. DHW recirculation in a private house will also work from a circulation pump, but with the obligatory connection of a thermostatic mixer. The fact is that the circuit with a coolant in this circuit is more susceptible to temperature changes, so the presence of a three-way system regulation unit will not be superfluous.

Since we are talking about a very responsible communication infrastructure with high loads on equipment, experts advise a comprehensive approach to accident prevention measures. At a minimum, the electrical basis of the boiler and boiler must include a safety block, as well as a voltage stabilizer, if we are talking about an electric boiler. In the case of gas equipment, it is recommended to use only flexible hoses when connecting. In a room with such units, effective ventilation must also be organized. It will not be superfluous to have a system for signaling malfunctions or depressurization. For example, Grundfos pumping units for DHW recycling provide an indication of the characteristics of the operating mode, the current parameters of the movement of the coolant and energy consumption. Periodically it is recommended to check the circuits for the quality of the connections. At the slightest deviation in pressure, pressure testing of the branches should be carried out - both in individual sections and in the complex.